Rhodium recovery_ How to recover metal rhodium from rhodium waste and rhodium black catalyst process method

The background of the process for recovering rhodium and the source of rhodium:So far, several different methods have been used to extract, concentrate, and purify rhodium. The main source of rhodium

The background of the process for recovering rhodium and the source of rhodium:

So far, several different methods have been used to extract, concentrate, and purify rhodium. The main source of rhodium includes its ore or any other material extracted from Earth and containing any natural form of rhodium. The secondary sources of rhodium include all materials previously used for other purposes that can extract rhodium, such as waste catalyst materials, platinum/rhodium thermocouple alloys, electrical contacts, etc. In order to recover rhodium from a primary source, the ore is generally crushed, finely ground, and then treated with flotation and magnetic methods to separate sulfide minerals. These sulfides are further separated to produce nickel concentrates containing the majority of platinum metals. Selective removal of copper and control of sulfur oxidation leaving nickel containing platinum metal as an impurity. This type of nickel is electrolytically refined and the platinum metal is recovered from the anode slime. In the treatment of anode slime, a method is needed to convert Platinum group into their ionic solution.

Two example processes for recovering metal rhodium from rhodium waste and rhodium black catalysts:

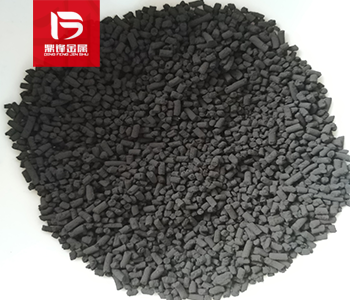

1. Under sufficient stirring, suspend 5.0 grams of rhodium black in a 1 liter aqueous solution containing 50 grams of table salt (sodium chloride), 40 grams of phosphoric acid, and 100 grams of sulfuric acid. Platinum plated titanium anode and lead cathode are used as electrodes, with an area ratio of approximately 1:1 between the cathode and anode, and an anode cathode gap of approximately 3 inches. Heat the solution to and maintain it at 90 degrees Celsius throughout the entire electrolysis process. Pass a 3 ampere current through the solution for 60 minutes, then filter the solution and analyze its rhodium content. Analysis shows that the solution contains 0.63 grams of metal rhodium per liter. Repeat this process until the solution no longer turns red after the electrolysis step is completed. Dissolve the cathode in nitric acid, recover the residual rhodium, and combine it with the rhodium recovered from the electrolyte by precipitation with hot formic acid. The total amount of rhodium recovered is 4.88 grams.

2. The prepared electrolyte contains 100g sulfuric acid, 60g sodium chloride and 30g phosphoric acid per liter. Platinum plated titanium anode and lead cathode are used as electrodes, with a surface area ratio of approximately 1:1 between the anode and cathode. The surface area of the cathode is approximately 0.9 square feet. During the electrolysis process, the solution temperature is maintained at 90 degrees Celsius and the cathode current density is 5 amperes per square foot. Will contain over 98% β 1000 grams of powdered aluminum oxide automotive catalyst material are suspended in the solution, while fully stirring to suspend most of the solid material. Stop electrolysis after 2 hours and treat the cathode and electrolyte solution according to Example I. Recycle 2.1 grams of rhodium.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;