Rhodium Recovery_Rhodium recycling What are the processes of rhodium?

Rhodium recycling involves several key steps to recover this valuable metal from various sources, such as spent catalysts, electronics, and other industrial waste. Here's an overview of the rhodiu

Rhodium recycling involves several key steps to recover this valuable metal from various sources, such as spent catalysts, electronics, and other industrial waste. Here's an overview of the rhodium recycling process:

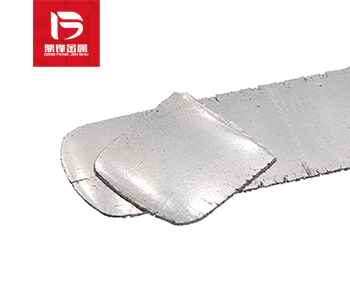

1. Collection

Collecting rhodium-containing waste materials is the first step. This can include spent catalytic converters, electronic components, and industrial by-products that contain rhodium.

2. Pre-processing

In this stage, the collected materials are cleaned and prepared for further processing. This may involve physical separation techniques to remove non-metallic components and to reduce the size of the materials for easier handling.

3. Leaching

Leaching involves using chemical solutions to dissolve rhodium from the waste materials. Common leaching agents include aqua regia (a mixture of hydrochloric and nitric acids) or other suitable solvents that can selectively dissolve rhodium while leaving other metals behind.

4. Separation

After leaching, the solution contains dissolved rhodium along with other metals. Various separation techniques, such as solvent extraction or ion exchange, are employed to isolate rhodium from other metals.

5. Precipitation

Once rhodium is separated, it can be precipitated out of the solution using specific reagents that cause rhodium to form solid particles. This step results in rhodium hydroxide or rhodium salts, which can be further processed.

6. Reduction

The precipitated rhodium compound is then subjected to reduction, often using hydrogen gas or other reducing agents, to obtain metallic rhodium. This step typically involves heating the material to high temperatures in a controlled environment.

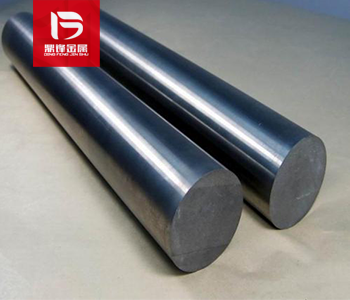

7. Refining

The recovered rhodium may undergo additional refining processes to achieve higher purity levels, ensuring it meets industry standards for various applications.

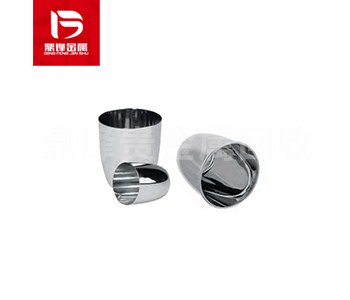

8. Reutilization

The final rhodium product can be used in various applications, including catalytic converters for vehicles, electronic components, and jewelry, thus contributing to a circular economy.

Conclusion

Rhodium recycling is an important process for resource conservation and environmental sustainability, as it helps reduce the need for primary mining while recovering valuable metals from waste materials.

Lastly, as precious metal recycling manufacturer, we don’t just buy rhodium. We also deal in palladium, platinum, gold, and silver.

Contact our friendly customer service at dfpmr5719@dfpmr.com and whatsapp +8613760175719 for more information and schedule an appointment today.