Palladium slurry recovery_ Palladium containing waste recycling_ Precious metal recycling manufacturers

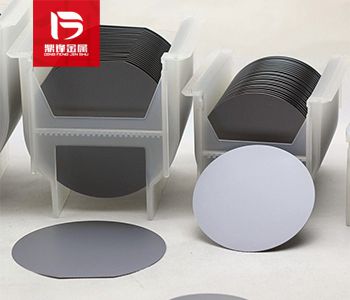

Palladium slurry is a fine granular material that contains high concentrations of palladium metal particles suspended in a solvent. These palladium particles are nanometer or submicron in size and usually appear gray or black in appearance. The preparation process of palladium slurry can be achieved by different methods, the most common of which is chemical synthesis. Waste palladium slurry is one of the sources of palladium-containing waste recycling. Other sources of palladium-containing waste recycling include palladium water recovery, palladium paste recovery, palladium slurry recovery, palladium graphite recovery, palladium slag recovery, palladium mud recovery, etc.

Product Details

Palladium slurry is a fine-grained substance that contains high concentrations of palladium metal particles suspended in a solvent. These palladium particles have nanoscale or submicron size and typically exhibit a gray or black appearance. The preparation process of palladium slurry can be achieved through different methods, the most common of which is chemical synthesis.

The production process of palladium slurry: 1. Selection of palladium metal: The first step in preparing palladium slurry is to select high-purity palladium metal as the raw material. These metals typically exist in powder or sheet form and require strict quality control to ensure their purity and consistency in composition. 2. Dispersion of palladium metal: Mix the selected palladium metal with the solvent to disperse the palladium metal into small particles. In this step, surfactants or dispersants are usually used to increase the dispersibility of palladium particles and prevent their aggregation. 3. Cleaning and filtration: In order to remove impurities and insoluble substances, the palladium slurry is cleaned by filtration or centrifugation. This step helps to improve the purity and stability of palladium slurry. 4. Concentration and drying: By evaporating the solvent or other appropriate methods, the solvent in the palladium slurry is removed to concentrate the content of palladium particles. Subsequently, the concentrated palladium slurry is dried using appropriate drying techniques to obtain stable palladium slurry products. 5. Characterization and testing: Finally, the prepared palladium slurry was characterized and performance tested using various instruments and testing methods. These tests can include particle size analysis, surface morphology observation, chemical composition analysis, and physical performance measurement.

Waste palladium slurry is one of the sources of palladium containing waste recycling, including palladium water recycling, palladium paste recycling, palladium slurry recycling, palladium graphite recycling, palladium slag recycling, palladium mud recycling, etc. If you have any demand for palladium containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has independent recycling and refining factories without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.

- Previous:No time

- Next:Palladium catalyst recovery_ Palladium asbestos recovery_ Pr