Palladium catalyst recovery_ Palladium asbestos recovery_ Precious metal recycling manufacturers

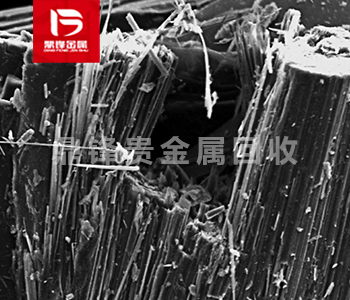

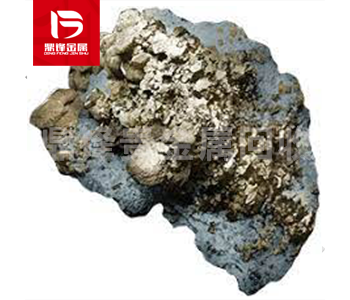

Palladium asbestos is a special composite material composed of palladium and asbestos fiber, with excellent physical and chemical properties. Palladium asbestos is a commonly used engineering material that combines the corrosion resistance of palladium with the high strength and high temperature resistance of asbestos fiber.

Product Details

Palladium asbestos is a special composite material composed of palladium and asbestos fibers, with excellent physical and chemical properties. Palladium asbestos is a commonly used engineering material that combines the corrosion resistance of palladium with the high strength and high-temperature resistance of asbestos fibers.

The production process of palladium asbestos includes the following steps:

1. Material preparation: The main components of palladium asbestos are palladium and asbestos fibers. Palladium is a rare metal that typically exists in the form of powder. Asbestos is a natural fiber ore with excellent high-temperature resistance and insulation properties. Before making palladium asbestos, it is necessary to prepare an appropriate amount of palladium powder and asbestos fibers.

2. Mixing: Mix palladium powder and asbestos fibers together. The purpose of mixing is to evenly disperse palladium powder in asbestos fibers, ensuring that the final palladium asbestos has uniform properties and organizational structure. Mixing is usually achieved through mechanical stirring or chemical methods.

3. Pressing: Place the mixed palladium asbestos into a pressing machine for pressing. By applying high pressure, the particles of palladium asbestos are tightly combined to form a solid billet. The pressure and time of pressing need to be determined according to specific process requirements.

4. Sintering: Place the pressed palladium asbestos blank into a high-temperature furnace for sintering. The purpose of sintering is to cause melting and bonding between palladium particles, forming a dense structure. During the sintering process, chemical reactions occur between palladium particles and asbestos fibers, thereby enhancing the mechanical properties and chemical stability of palladium asbestos.

5. Forming and processing: The sintered palladium asbestos blank can be further formed and processed. According to specific application requirements, palladium asbestos can be processed into various shapes and sizes by methods such as cutting, turning, and drilling to adapt to different engineering designs.