Iridium ore powder recovery_ Iridium powder recycling price_ Precious metal recycling and refining manufacturers

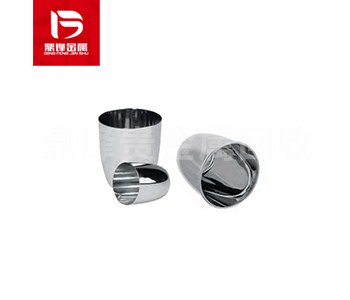

Iridium is a platinum group metal with a high melting point, high density and good corrosion resistance. It is one of the rarest elements in the earth's crust and often exists in the form of iridium ore. Iridium ore powder has a fine particle size and a large specific surface area, which gives it excellent catalytic activity and adsorption properties. Waste iridium ore powder is one of the important sources of iridium-containing waste recycling. Iridium-containing waste recycling also includes iridium-rhodium alloy recycling, iridium rod recycling, crude iridium recycling, iridium block recycling, iridium tube recycling, iridium crucible recycling, iridium powder recycling, and iridium wire recycling.

Product Details

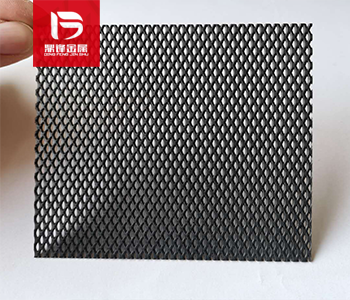

Iridium is a Platinum group with high melting point, high density and good corrosion resistance. It is one of the rarest elements in the Earth's crust, often present in the form of iridium ore. Iridium ore powder has a small particle size and a large specific surface area, which gives it excellent catalytic activity and adsorption performance. In addition, iridium ore powder also has good conductivity and thermal stability, making it widely used in the electronics industry and high-temperature environments.

The preparation of iridium ore powder usually includes the following steps:

1. Ore mining and crushing: Iridium ore is extracted from underground deposits. Firstly, mining workers use methods such as blasting or drilling to extract the ore and then transport it to the processing plant. In the processing plant, the ore is crushed by crushing machinery and equipment to become small particles suitable for further processing.

2. Leaching and concentration: Iridium ore after crushing usually contains other impurities. In order to extract pure iridium, a leaching and concentration process is required. During the leaching process, ore particles are immersed in acidic or alkaline solutions to dissolve iridium. Then, iridium is separated from the solution through chemical reactions or physical methods and further concentrated.

3. Filtering and drying: The concentrated iridium solution is filtered to remove residual impurities and solid particles. The filtered liquid is fed into a drying device and converted into a solid iridium substance.

4. Crushing and refinement: Dry iridium materials usually form blocky or granular shapes and require crushing and refinement treatment. This step uses specialized crushing equipment to finely crush the iridium material into small particles. The crushed iridium material can be further refined through screening and other methods to obtain the required particle size and uniformity.

5. Powder treatment and surface treatment: The crushed iridium material is rough and requires further treatment to improve its physical and chemical properties. This includes removing impurities, adjusting particle size and shape, and conducting surface treatment. Common treatment methods include heat treatment, chemical treatment, and mechanical treatment.

6. Powder classification and grading: The application of iridium ore powder requires a certain particle size and uniformity. Therefore, powders usually need to be classified and graded to remove particles that do not meet the requirements and obtain the required particle size distribution.

7. Packaging and Storage: Finally, iridium ore powder is usually packaged in sealed containers according to different application requirements and stored in dry, low temperature, and low humidity environments to maintain its quality and performance.

Waste iridium ore powder is one of the important sources of iridium containing waste recycling. Iridium containing waste recycling also includes iridium rhodium alloy recycling, iridium rod recycling, crude iridium recycling, iridium block recycling, iridium tube recycling, iridium crucible recycling, iridium powder recycling, and iridium wire recycling. If you have any demand for iridium containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has its own recycling and refining factory without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.