Recovery of ruthenium iridium titanium mesh_ Recovery price of ruthenium iridium titanium mesh electrode_ Precious metal recycling and refining manufacturers

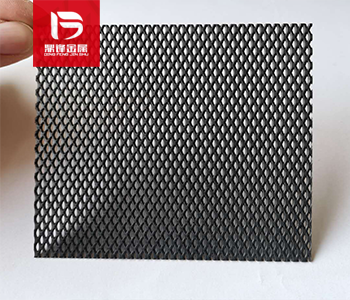

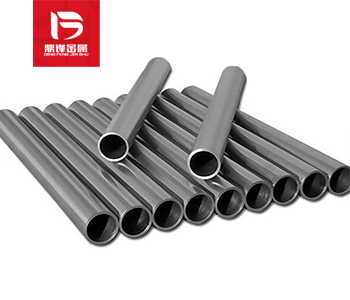

Ruthenium-iridium titanium mesh is often used to make exquisite decorations, handicrafts and other items due to its excellent electroplating properties. Waste ruthenium-iridium-titanium mesh is one of the recycling sources of ruthenium-containing scraps. The recycling sources of ruthenium-containing scraps include ruthenium wire recycling, ruthenium sheet recycling, ruthenium particle recycling, ruthenium powder recycling, iridium-titanium anode coating recycling, etc.

Product Details

Ruthenium iridium titanium mesh is currently an emerging material in the environmental protection and electroplating industries. Due to its excellent electroplating performance, ruthenium iridium titanium mesh is commonly used to make exquisite decorations, handicrafts, and other items. Ruthenium iridium titanium mesh can also be used as an electrode material, with the following advantages:

1. The anode size is stable, and the spacing between electrodes does not change during the electrolysis process, ensuring that the electrolysis operation is carried out under stable cell voltage

2. Low working voltage, low energy consumption, can reduce consumption by about 20%

3. Titanium anodes have a long working life, and in the chlorine gas production industry using the diaphragm method, metal anodes are resistant to chlorine and alkali corrosion

4. It can overcome the problem of graphite anode and lead anode dissolution, avoid contamination of electrolyte and cathode products, and improve product quality

5. It can increase the current density. For example, in the production of chlor alkali using the diaphragm method, the current density of the graphite electrode is 8A/dm2, and the titanium anode can increase exponentially to 17A/dm2. This way, the production can be doubled in the same electrolysis plant and cell

6. Strong corrosion resistance, suitable for working in many highly corrosive and special electrolytic media

7. It can avoid short circuit problems after deformation of the lead anode, thereby improving current efficiency

8. The matrix titanium material can be reused

Waste ruthenium iridium titanium mesh is one of the recycling sources of ruthenium containing waste. The recycling sources of ruthenium containing waste include ruthenium wire recycling, ruthenium sheet recycling, ruthenium slag recycling, ruthenium particle recycling, ruthenium ingot recycling, ruthenium powder recycling, iridium titanium anode coating recycling, etc. If you have any demand for the recycling of ruthenium containing waste, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has independent recycling and refining factories without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.