Tantalum oxide recovery_ Recovery price of Tantalum pentoxide_ Rare metal catalyst recycling manufacturer

Tantalum oxide generally refers to tantalum pentoxide, which is a rare metal catalyst whose appearance is white colorless crystalline powder. Tantalum oxide is the most common oxide of tantalum and the final product of tantalum combustion in air. It is mainly used for pulling lithium tantalate single crystal and manufacturing high-refraction and low-dispersion special optical glass, and can be used as a catalyst in chemical industry. Waste tantalum oxide is one of the sources of tantalum waste recycling. Tantalum waste recycling also includes tantalum capacitor recycling, tantalum wire recycling, tantalum powder recycling, tantalum tube recycling, tantalum rod recycling, tantalum alloy recycling, and tantalum block recycling.

Product Details

Tantalum oxide generally refers to Tantalum pentoxide, which is a rare metal catalyst with white colorless crystalline powder. It is mainly used to make Lithium tantalate single crystal and special optical glass with high refraction and low dispersion, and can be used as catalyst in chemical industry. The preparation of tantalum oxide can be divided into two methods: Potassium heptafluorotantalate method and tantalum oxidation method.

With the Potassium heptafluorotantalate method, Potassium heptafluorotantalate and sulfuric acid are heated to 400 ℃, the reactant is boiled with water, and the acidified solution is fully diluted to hydrolyze to generate hydrated oxide precipitation, which is then separated, washed, and dried to obtain Tantalum pentoxide finished products. The 2K2TaF7+2H2SO4+5H2OTa2O5+2K2SO4+14HF tantalum oxidation method dissolves tantalum flakes in nitric acid and hydrofluoric acid, extracts and purifies them, precipitates tantalum hydroxide with ammonia, and then washes, dries, burns and grinds them to obtain Tantalum pentoxide finished products.

Metal tantalum oxidation method: Dissolve the metal tantalum sheet in a mixture of nitric acid and hydrofluoric acid, extract and purify it, and precipitate tantalum hydroxide with ammonia water. After washing, drying, burning and grinding, the finished Tantalum pentoxide is obtained.

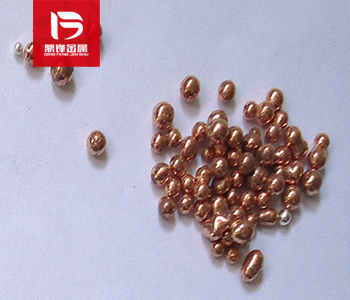

Waste tantalum oxide is one of the sources of tantalum waste recycling, including tantalum capacitor recycling, tantalum wire recycling, tantalum powder recycling, tantalum tube recycling, tantalum rod recycling, tantalum alloy recycling, tantalum block recycling, etc. If you have any demand for tantalum containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has its own recycling and refining factory without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.