Palladium catalyst recovery_ Palladium alumina recovery price_ Precious metal catalyst recovery and refining manufacturer

Palladium catalyst is a palladium catalyst with aluminum oxide as carrier, also known as palladium alumina. Palladium catalyst is widely used in metallurgy, electronics, chemical industry and other industries for deep purification and deoxygenation of hydrogen, nitrogen, argon and other gases in these industries. Waste palladium catalyst is also one of the sources of palladium-containing precious metal catalyst recycling. Other sources of palladium-containing precious metal catalyst recycling include palladium chloride recycling, palladium oxide recycling, palladium nitrate recycling, palladium acetate recycling, palladium iodide recycling, etc.

Product Details

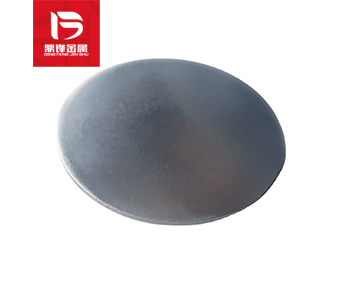

Palladium catalyst is a type of palladium catalyst supported on alumina, also known as palladium alumina. Palladium catalysts are widely used in industries such as metallurgy, electronics, and chemical engineering for deep purification and deoxygenation of gases such as hydrogen, nitrogen, and argon in these industries. Palladium catalyst is a thin shell type deoxygenation catalyst with high catalytic activity, simple operation, long service life, and high safety, using alumina as the carrier.

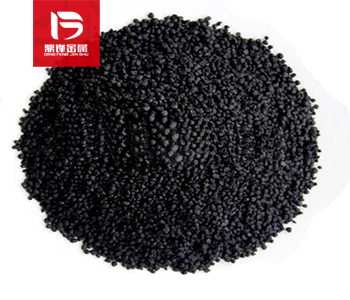

The palladium catalyst has a spherical shape with a diameter of approximately 3-5mm and a grayish black appearance color. There are various types of palladium catalysts with low palladium content ranging from 0.3% to 0.6%, as well as 1%, 3%, and 5%. The types of palladium content vary greatly depending on the needs of the application industry, so the detection of palladium content is very important in palladium carbon recovery. The carrier of palladium catalyst is aluminum oxide. At room temperature, with a space velocity range of 8000-1800h-1, an ideal effect can be achieved by passing through the catalyst bed layer in one pass.

A palladium catalyst used for complete deoxidation of gases such as oxygen, nitrogen, and argon. Its working principle is that when the feed gas passes through the catalyst, oxygen impurities in the gas can react with hydrogen to produce water, thereby achieving the catalytic effect of deoxidation. Palladium catalyst, as a Oxygen scavenger for such gases, is characterized by non degradation, high activity and good strength. In the anaerobic cultivation of microorganisms, palladium catalysts are also applied. After the successful completion of the extraction and replacement process, the oxygen content in the cultivation tank can be reduced to a minimum as much as possible. Then, through the promotion effect of palladium catalyst, the hydrogen gas in the mixed gas undergoes a catalytic reaction with a small amount of oxygen remaining in the tank, forming water vapor through the reaction, and achieving oxygen elimination through operation, creating a naturally anaerobic environment

Waste palladium catalysts are also one of the sources of recovery of palladium containing noble metal catalysts. The recovery sources of palladium containing noble metal catalysts include Palladium(II) chloride recovery, Palladium(II) oxide recovery, Palladium(II) nitrate recovery, palladium acetate recovery, Palladium(II) iodide recovery, etc. If you have any demand for palladium containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has independent recycling and refining factories without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.