Ruthenium slurry recovery_ Recovery price of ruthenium slurry_ Ruthenium containing waste recycling and refining manufacturer

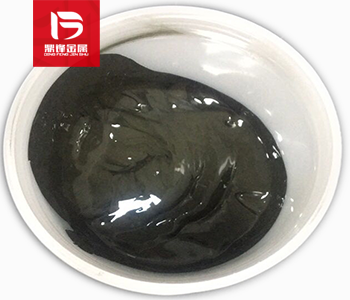

Ruthenium paste, also known as ruthenium paste, refers to the precious metal paste containing ruthenium. An important industrial use of ruthenium paste is as a resistance paste, and can also be used to manufacture various metal parts, such as auto parts, electronic components, mechanical parts, etc. Waste ruthenium slurry is one of the recycling channels for ruthenium-containing waste. The recycling channels for ruthenium-containing waste include ruthenium water recovery, ruthenium slurry recovery, ruthenium slag recovery, ruthenium powder recovery, ruthenium carbon recovery, ruthenium wire recovery, ruthenium block recovery, etc.

Product Details

Ruthenium slurry, also known as ruthenium slurry, refers to precious metal slurry containing ruthenium. Ruthenium paste is a kind of binder, which has an important industrial use as resistance paste, and can also manufacture various metal parts, such as automobile parts, electronic components, Machine element, etc. Resistance slurry is a slurry that uses precious metals as the conductive phase and is used for assembling thick film resistors, with ruthenium based slurry being the most commonly used. Ruthenium resistance paste is a paste that can be used for printing or coating, which is composed of Ruthenium(IV) oxide powder, ruthenium salts, inorganic additives as conductive materials and organic carriers. It can be used to make thick film resistors, resistance networks, hybrid integrated circuits and resistors and electrodes for specific purposes. This resistance paste has the advantages of good Chemical equilibrium, Thermal equilibrium and moisture resistance, high precision and wide range of resistance value, small resistance temperature coefficient, low noise of high resistance, good reproducibility of resistance value, good compatibility with silver based conduction band, and good environmental balance. The pressing conditions for ruthenium resistance slurry are: the peak pressing temperature is 840-860 ℃, the peak holding time is 8-10 minutes, and the heat treatment cycle is 30-60 minutes. Waste ruthenium slurry is one of the recycling channels for ruthenium containing waste. The recycling channels for ruthenium containing waste include ruthenium water recycling, ruthenium slurry recycling, ruthenium slag recycling, ruthenium powder recycling, ruthenium carbon recycling, ruthenium wire recycling, ruthenium block recycling, etc. If you have any demand for the recycling of ruthenium containing waste, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has independent recycling and refining factories without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.