How Dingfeng Recovers Iridium from Industrial Catalysts

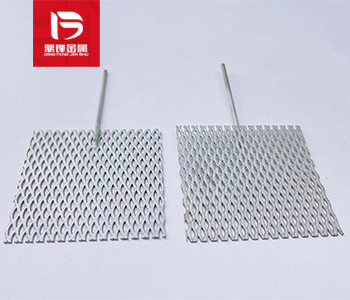

Industrial catalysts, particularly those used in chemical manufacturing, are a major source of iridium scrap. These catalysts, once spent, still contain significant amounts of recoverable iridium. At Dingfeng Precious Metals Recovery, we have developed specialized hydrometallurgical techniques to extract iridium efficiently while maintaining the integrity of the carrier material.

Product Details

Industrial catalysts, particularly those used in chemical manufacturing, are a major source of iridium scrap. These catalysts, once spent, still contain significant amounts of recoverable iridium. At Dingfeng Precious Metals Recovery, we have developed specialized hydrometallurgical techniques to extract iridium efficiently while maintaining the integrity of the carrier material.

Our process includes:

✔ Pre-sorting and analysis (XRF testing to determine exact iridium content)

✔ Acid-free extraction methods (reducing environmental hazards)

✔ High-temperature refining (ensuring 99.95%+ purity)

A recent case study with a European chemical plant demonstrated how our optimized recovery process increased their iridium yield by 37%, translating to $250,000+ in additional annual revenue.

We also offer on-site collection services, ensuring safe and compliant handling of hazardous materials. Whether you deal with acetic acid catalysts, hydrogenation waste, or other PGM-bearing materials, Dingfeng provides end-to-end solutions for maximizing your returns.

Request a quote today and learn how our expertise in catalyst recycling can benefit your business.