The Critical Importance of Iridium Recycling in Modern Industry

By choosing Dingfeng for your iridium recycling needs, you contribute to a circular economy while benefiting from competitive returns. Contact us today for a free scrap evaluation and discover how your waste can be transformed into valuable resources.

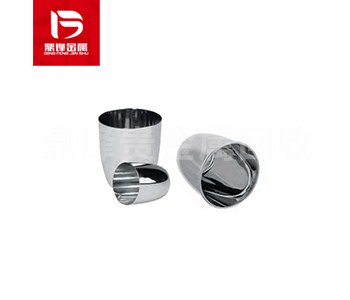

Product Details

As industries worldwide strive for greater sustainability, the recycling of precious metals like iridium has become increasingly critical. Iridium, known for its exceptional hardness and corrosion resistance, is widely used in high-tech applications such as aerospace components, medical devices, and green energy technologies. However, primary iridium mining is both environmentally damaging and economically costly. At Dingfeng Precious Metals Recovery, we specialize in extracting maximum value from iridium scrap while minimizing environmental impact.

Our advanced recovery processes ensure that iridium-bearing materials—such as spent chemical catalysts, electronic waste, and industrial crucibles—are efficiently processed to achieve 99.9% purity. This not only conserves natural resources but also provides significant cost savings for manufacturers. For example, recycling iridium from used catalysts can reduce production costs by up to 40% compared to sourcing newly mined material.

Additionally, with global iridium prices remaining high due to limited supply, recycling offers a lucrative opportunity for businesses to monetize their scrap. Dingfeng provides transparent pricing based on real-time market rates, along with secure logistics and full assay certification.

By choosing Dingfeng for your iridium recycling needs, you contribute to a circular economy while benefiting from competitive returns. Contact us today for a free scrap evaluation and discover how your waste can be transformed into valuable resources.