Platinum iridium alloy recycling_ Platinum iridium electrode recovery_ Precious metal recycling manufacturers

Platinum-iridium alloy is an alloy composed of two precious metal elements, platinum (Pt) and iridium (Ir). This alloy is widely used in many fields due to its excellent properties, especially in high temperature and corrosive environments. Platinum-iridium alloy has good corrosion resistance, high melting point, excellent mechanical strength and wear resistance, so it is widely used in aerospace, chemical, medical and jewelry industries.

Product Details

Platinum iridium alloy is an alloy composed of two precious metal elements, platinum (Pt) and iridium (Ir). This alloy has been widely used in many fields due to its excellent properties, especially in high-temperature and corrosive environments. Platinum iridium alloys have excellent corrosion resistance, high melting point, excellent mechanical strength, and wear resistance, making them widely used in industries such as aerospace, chemical, medical, and jewelry.

The production of platinum iridium alloy is a complex and delicate process, mainly including the following steps:

1. Preparation of raw materials: The first step in the production of platinum iridium alloy is to prepare an appropriate amount of platinum and iridium raw materials. Usually, these two metals exist in the form of powders. Determine the ratio of the two raw materials by weight or atomic percentage based on the required alloy ratio.

2. Mixing and grinding: Place the prepared platinum and iridium powder in a container for mixing. The purpose of mixing is to ensure a uniform distribution of platinum and iridium, in order to achieve consistency and stability of the alloy. The mixed powder needs to be ground to increase surface area and improve reactivity.

3. Pressing: The platinum iridium powder after mixing and grinding needs to be pressed. This step uses a special pressing device to place the powder into the mold and apply high pressure to form a dense billet. The purpose of pressing is to increase the density and strength of the alloy.

4. Sintering: The pressed platinum iridium billet needs to be sintered. Sintering refers to heating the billet at high temperature, causing diffusion and bonding between metal powder particles. This can further increase the density and strength of the alloy, as well as improve its physical and mechanical properties.

5. Heat treatment: The sintered platinum iridium alloy needs to undergo heat treatment. Heat treatment is the heating process of exposing an alloy to specific temperature and time conditions. By controlling heat treatment parameters, the crystal structure and mechanical properties of the alloy can be improved, internal stress can be eliminated, and its corrosion resistance can be improved.

6. Processing and Forming: Platinum iridium alloys that have undergone heat treatment can be made into the required shapes and sizes through various processing and forming methods. For example, precise machining of alloys can be carried out using mechanical machining (milling, turning, drilling, etc.). In addition, complex shaped platinum iridium alloy products can also be prepared through technologies such as casting, melting, or 3D printing.

7. Surface treatment: Finally, the completed platinum iridium alloy may require surface treatment to improve its appearance and corrosion resistance. For example, electroplating, spraying, or oxidation treatment can be carried out to enhance the aesthetics and corrosion resistance of the alloy.

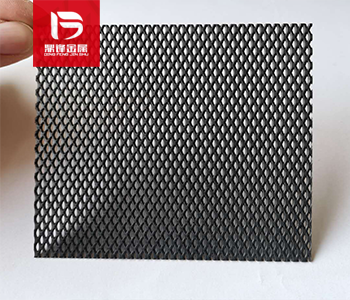

Waste platinum iridium alloys are one of the sources of platinum containing waste recycling. Platinum containing waste recycling also includes platinum rhodium block recycling, platinum ash recycling, platinum alloy recycling, platinum mesh recycling, platinum rhodium wire recycling, platinum gold wire recycling, platinum rhodium leakage plate recycling, platinum mesh recycling, titanium plating platinum recycling, etc. If you have any demand for platinum containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has its own recycling and refining factory without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.