Our Platinum Recycling Process: Precision & Transparency

We deploy cutting-edge smelting, chemical leaching, and electrolytic refining to recover platinum from: Spent automotive catalysts (petrol & diesel) Industrial catalysts (chemical, oil & gas) Electronic scrap (circuit boards, contacts) Jewelry & dental alloys

Product Details

We deploy cutting-edge smelting, chemical leaching, and electrolytic refining to recover platinum from:

Spent automotive catalysts (petrol & diesel)

Industrial catalysts (chemical, oil & gas)

Electronic scrap (circuit boards, contacts)

Jewelry & dental alloys

Key Steps:

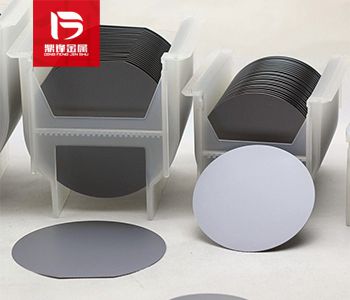

Material Assessment – XRF & lab testing for exact platinum content

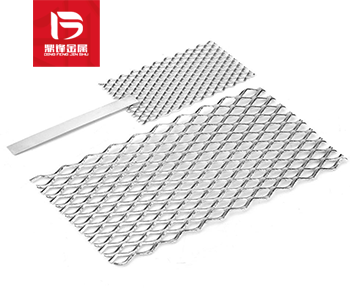

Advanced Separation – Mechanical & chemical extraction

High-Purity Refining – Up to 99.99% pure platinum

Full Reporting – Mass balance & ESG impact statements

Industries We Serve

We tailor solutions for:

Automotive – Recycling catalytic converters at scale

Chemicals & Oil Refining – Platinum/palladium catalyst recovery

Electronics – Extracting platinum from e-waste

Medical & Dental – Reclaiming platinum from old equipment

Why Choose Dingfeng?

Highest Recovery Rates – Optimized processes for maximum yield

Global Reach – Logistics hubs in Europe, Asia & Americas

Competitive Pricing – Real-time London Platinum Market pricing

Zero-Waste Policy – 100% of byproducts responsibly processed

Turn Scrap Platinum Into Profit Today

Get a free evaluation of your platinum-bearing materials:

Call: [+8613760175719]

Email: [dfpmr5719@dfpmr.com]

Dingfeng Precious Metals – Closing the Loop on Platinum Sustainability.