The specific steps for recycling gold-plated circuit boards and waste materials

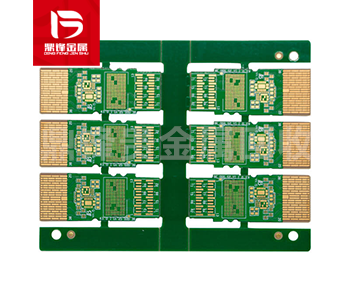

Gold plated circuit board recycling refers to the recycling and reuse of discarded electronic circuit boards containing precious metal (such as gold and silver) coatings. The commonly used precious me

Gold plated circuit board recycling refers to the recycling and reuse of discarded electronic circuit boards containing precious metal (such as gold and silver) coatings. The commonly used precious metal coating in electronic circuit boards is mainly to improve conductivity, corrosion resistance, and reliability. The purpose of gold plated circuit board recycling is to recover precious metals from discarded electronic devices and reuse them to reduce the demand for natural resources, reduce environmental pollution, and energy consumption. The following are the specific process steps for recycling gold plated circuit board waste:

1. Collection and sorting: The first step in the recycling process is to collect the waste of gilded circuit boards. These waste materials can come from used electronic products, electronic equipment manufacturing factories, or other electronic waste recycling centers. Once the waste is collected, it needs to be sorted. Classify the discarded circuit boards according to their type, specifications, metal content, etc. for subsequent disposal.

2. Remove non-metallic parts: After sorting, the discarded circuit boards need to be pre-treated to remove non-metallic parts. This includes using mechanical methods such as crushing and crushing to break down the circuit board into smaller pieces. Next, physical or chemical methods can be used to remove non-metallic parts on the circuit board, such as plastic, rubber, and other impurities through vibration screening, magnetic separation, and soaking.

3. Acid soaking: Once the non-metallic parts are removed, the remaining high metal content circuit board fragments can be subjected to acid soaking. This is achieved by soaking circuit board fragments in an acidic solution containing hydrochloric acid and nitric acid to remove oxide layers and other pollutants from the metal surface. Acid soaking can help improve the recovery rate of metals.

4. Metal separation: After acidic immersion, the metal part is separated from other impurities dissolved in the acidic solution. A common method is to separate metals through electrochemical processes. In this process, the circuit board fragments are placed into an electrolytic cell to become the cathode, and the metal plate or rod serving as the anode passes the current through the solution. Metal ions will precipitate and deposit on the cathode in the electrolytic cell. This achieves the separation and recovery of metals.

5. Metal refining: The separated metal may still contain some impurities, and refining treatment is needed to improve the purity and quality of the metal. Metal refining can use various methods, such as electrolytic refining, smelting, and chemical reduction. Through these processes, the purity of the metal is improved, and higher quality metal materials can be obtained.

6. Metal sales or reuse: The refined metal can be sold or reused. High purity metals can be used in industries such as electronic manufacturing, jewelry making, electroplating, etc. In this way, the waste of gold-plated circuit boards is recycled, reducing the demand for raw resources and reducing the negative impact on the environment.

7. Environmental treatment: During the waste recycling process, special attention needs to be paid to environmental protection. Waste acidic solutions and other treatment liquids need to be treated to avoid pollution to the environment. Neutralization, sedimentation, filtration and other methods can be used to treat the waste liquid to remove harmful substances and ensure compliance with environmental protection standards.

8. Regular monitoring and improvement: The waste recycling process needs to be regularly monitored and evaluated to ensure the effectiveness of the process and environmental safety. By monitoring indicators such as metal recovery rate, waste liquid treatment effect, and environmental impact after waste treatment, problems can be identified in a timely manner and improvement measures can be taken.

Through the above steps, the recycling process of gold-plated circuit board waste can be completed. This type of waste recycling not only contributes to resource conservation and reuse, but also reduces damage to the natural environment. In the future, with the continuous progress of technology, the efficiency and environmental friendliness of waste recycling will be further improved, and the goal of promoting sustainable development will be achieved.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;