Do you know the specific steps for extracting silver from waste silver contacts?

Recycling and extracting silver from waste silver contacts is an important environmental protection and resource reuse work. This process can minimize the waste of waste silver and extract valuable si

Recycling and extracting silver from waste silver contacts is an important environmental protection and resource reuse work. This process can minimize the waste of waste silver and extract valuable silver from it. The following is a detailed procedure that introduces the specific process of extracting silver from waste silver contacts.

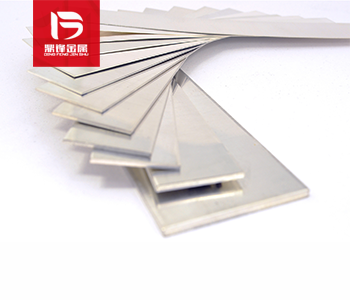

Step 1: Collect waste silver contacts

Collecting waste silver contacts is the primary task of the entire recycling and refining process. Scrap silver contacts typically come from discarded electronic devices such as computers, mobile phones, and electronic circuit boards. Recycling enterprises can collaborate with electronic waste treatment centers or directly establish contact with various electronic equipment manufacturers to obtain these waste silver contacts. The collected waste silver touchpoints will be sent to the next processing step.

Step 2: Physical processing

During the physical treatment process, the waste silver contact points will be decomposed into smaller components for better subsequent chemical treatment. This process includes removing any non silver impurities such as plastic, rubber, and other metals. Physical treatment typically includes grinding, screening, and washing steps to ensure the purity of waste silver contacts.

Step 3: Chemical treatment

In the chemical treatment stage, the waste silver contacts that have undergone physical treatment will be further processed to extract silver. Firstly, soak the waste silver contacts in a chemical solution called an extractant. This extraction agent is usually an organic solvent that can selectively dissolve silver without dissolving other impurities. The selection of extractant is very important because it must be efficient, selective, and economical.

Step 4: Solution treatment

After a period of immersion, the silver in the solution has been extracted into the organic phase. Next, contact the organic phase with a substance called an extractant. The extractant has silver affinity and can separate silver from the organic phase. This step usually uses a reverse extraction method, using a solvent called a reverse extractant to remove silver from the extractant.

Step 5: Electrolytic refining

After solution treatment, a solution containing silver has been obtained. The next step is to separate silver from the solution through an electrolytic refining process. This step is usually achieved using an electrolytic cell. Firstly, it is necessary to prepare an electrolytic cell, which is filled with electrolyte. The electrolyte is usually a Silver nitrate solution containing silver ions. At the same time, place two electrodes into the electrolytic cell, one of which is the anode of pure silver and the other is the cathode of waste silver contacts. After starting the electrolytic cell, the current will flow through the electrolyte and electrodes. During this process, silver ions are reduced to pure silver, which is then deposited on the cathode. At the same time, the pure silver on the anode will be oxidized into silver ions, which will re-enter the solution. In this way, the cathode will gradually accumulate enough pure silver to be collected and further processed.

Step 6: Purification and melting

The collected pure silver needs further purification and smelting to remove other impurities that may exist. This step usually includes chemical treatment and high-temperature melting.

In chemical treatment, acid washing or other methods can be used to remove residual impurities. This will ensure that the final extracted silver has a higher purity.

Then, the purified silver is placed in a furnace for high-temperature melting. At high temperatures, silver will melt into a liquid state, and any remaining impurities will float on the surface to form slag. By pouring or other methods, slag can be separated from pure silver to obtain purer silver.

Step 7: Preparation of Silver Ingot

The final step is to cast the purified silver into silver ingots. Pour the molten silver into the silver ingot mold and allow it to cool and solidify. Once the silver ingot has completely solidified, it can be removed and subjected to surface treatment, such as polishing and polishing, to obtain a smooth surface.

The recovery and extraction of silver from waste silver contacts is a complex process that involves multiple steps such as collection, physical treatment, chemical treatment, solution treatment, electrolytic refining, purification and smelting, as well as the preparation of silver ingots. Through these steps, waste silver contacts can be effectively recovered and refined into high-purity silver. This process not only contributes to environmental protection and reduces resource waste, but also recycles valuable silver for reuse.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;