Silver contact recycling: methods and techniques for recycling waste silver contacts

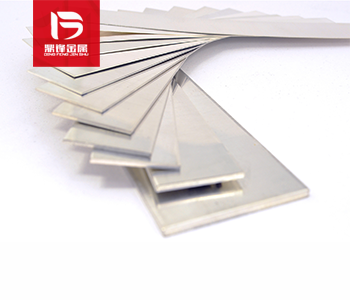

Scrap silver contacts refer to silver electronic components that have been discarded or lost in use, usually from electronic waste such as old appliances, electronic equipment, circuit boards, etc. Du

Scrap silver contacts refer to silver electronic components that have been discarded or lost in use, usually from electronic waste such as old appliances, electronic equipment, circuit boards, etc. Due to silver being an important precious metal with good conductivity and antioxidant properties, recycling waste silver contacts is a beneficial environmental protection and resource utilization method. The following will introduce the methods and technologies for recycling waste silver contacts.

1、 The significance of contact recycling

Waste silver contacts mainly come from electronic components such as discarded electronic devices, switches, and relays. Silver is a valuable resource. Recycling waste silver contacts can save a lot of natural resources and reduce the demand for new silver mining. In addition, silver contacts may contain other harmful substances such as mercury, which can effectively reduce environmental pollution through recycling and treatment.

2、 Method for recycling waste silver contacts

1. Mechanical separation method: Mechanical separation method is a traditional method of recycling waste silver contacts, which uses mechanical force to separate the silver contacts from waste electrical appliances. This method has the advantages of simplicity and low cost, but the separation effect is not ideal and is prone to generating a large amount of waste residue.

2. Chemical method: Chemical method is a popular method for recovering waste silver contacts, mainly including leaching method, hydrothermal method, microwave method, ultrasonic method, etc. These methods extract silver contacts from electronic waste through chemical dissolution or physical interactions. Chemical methods have the advantages of high recovery rate and good separation effect, but they require a certain amount of chemical drugs to be consumed, which can have a certain impact on the environment.

3. Baking method: Baking method is a high-temperature treatment method that uses high-temperature oxidation to decompose organic substances in electronic waste, thereby separating silver contacts. This method has the advantages of high recovery rate and simple operation, but it requires a large amount of energy consumption and can generate a large amount of harmful gases such as carbon dioxide, which has a serious impact on the environment.

3、 Technology for recycling waste silver contacts

1. Electrolysis method: Electrolysis method is a commonly used technology for recycling waste silver contacts, which uses electrochemical principles to separate silver contacts from electronic waste. The specific operation is to immerse electronic waste in an electrolyte and reduce silver ions into metallic silver through the action of an electric current, thereby achieving the goal of recycling. The electrolysis method has the advantages of high recovery rate and good separation effect, but it requires a large amount of electricity and electrolyte consumption, and the operation is relatively complex.

2. Gas phase extraction method: Gas phase extraction method is a relatively new technology for recycling waste silver contacts, which uses gas phase chemical reactions to separate silver from electronic waste. This method first heats the electronic waste to a certain temperature, causing the silver contacts to evaporate into a gaseous state, and then recondenses the silver gas into solid silver through a condensation collector. The gas phase extraction method has the advantages of high efficiency, no production of chemical waste, and minimal environmental impact, but the equipment investment is relatively large.

3. Magnetic separation method: Magnetic separation method is a technology that uses magnetic materials to separate waste silver contacts. This method achieves separation by utilizing the magnetic difference between silver contacts and magnetic materials under the action of a magnetic field. Firstly, after pre-treatment of waste electronic waste, the material containing silver contacts is placed in a magnetic field, and the silver contacts are adsorbed onto the magnetic material using the adsorption effect of the magnetic material. Then, the silver contacts are separated from the magnetic material through changes in the magnetic field. The magnetic separation method has the advantages of high efficiency and low cost, but the effect is not ideal for waste electronic waste with low silver contact content.

4. Carbon adsorption method: Carbon adsorption method is a technology that uses activated carbon to adsorb and separate waste silver contacts. This method involves contacting waste electronic waste with activated carbon, utilizing the adsorption characteristics of activated carbon to adsorb silver contacts onto the activated carbon, and then desorbing silver from the activated carbon through pyrolysis or other methods. Carbon adsorption method has the advantages of high recovery rate and renewable utilization of adsorbent, but it may have a certain impact on other impurities in complex waste electronic waste.

The above introduces the methods and technologies for recycling waste silver contacts, including different recovery methods such as mechanical separation, chemical method, and calcination, as well as different recovery technologies such as electrolysis, gas phase extraction, magnetic separation, and carbon adsorption. Each method and technology has its unique advantages and disadvantages, and suitable recycling methods can be selected based on specific circumstances.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;