Types and methods of precious metal recycling in solar panels

With the rapid development of renewable energy technology, solar panels are becoming increasingly popular. However, with the widespread application of solar panels and the gradual arrival of their ser

With the rapid development of renewable energy technology, solar panels are becoming increasingly popular. However, with the widespread application of solar panels and the gradual arrival of their service life, the treatment and recycling of waste solar panels have become an urgent issue that needs to be addressed. In these discarded solar panels, there is a certain amount of precious metals. Recycling these precious metals can not only reduce resource waste, but also bring economic benefits to enterprises. This article will explore the types and methods of recyclable precious metals in solar panels.

1、 Types of recyclable precious metals in solar panels

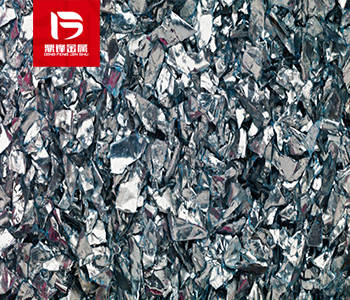

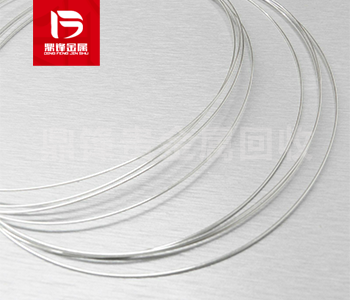

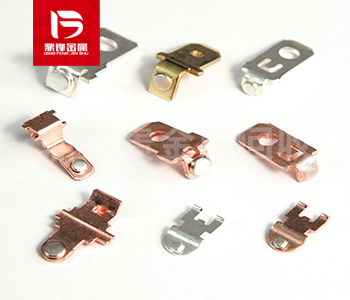

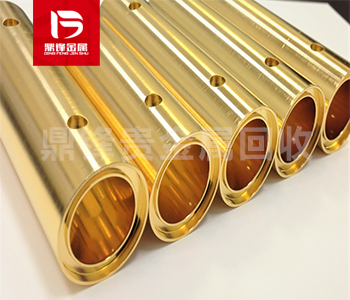

Silver (Ag): The most important precious metal in solar panels is silver. Silver is mainly used as a conductive paste in battery panels to form electrodes and interconnects for battery cells. Due to its excellent conductivity and chemical stability, silver is widely used in the manufacturing process of solar panels. Abandoned solar panels contain a certain amount of silver, which can be recycled to reduce resource waste. Indium (In): Indium is mainly used to manufacture CIGS (copper indium gallium selenium) thin film solar cells. CIGS battery is an efficient and lightweight solar cell technology, gradually becoming the mainstream of thin film solar cells. Although the content of indium is relatively low, its price is high, so recycling has certain economic value. Palladium (Pd): Palladium is mainly used to make conductive films in flexible solar cells. Although palladium has relatively few applications in solar panels, it still has high economic value for recycling due to its high price.

2、 Method for recycling precious metals from solar panels

Mechanical method: Mechanical method is the process of crushing, screening, and air flotation of waste solar panels through physical methods to separate precious metals from other materials. This method is simple to operate and relatively low-cost, but the recovery rate and purity are limited by equipment performance and operating skills. Wet method: Wet method involves soaking and leaching solar panels with chemical solvents to dissolve precious metals from waste solar panels. Next, the precious metals in the solution are purified and recovered through methods such as chemical precipitation, electrolysis, and ion exchange. This method has a high recovery rate and purity, but it involves the use of chemicals and waste liquid treatment, which may have a certain impact on the environment. Thermal method: Thermal method is the process of melting and separating precious metals from other materials in waste solar panels through high-temperature melting. The thermal method has the advantages of large processing capacity and high recovery purity, but it requires high energy consumption and professional smelting equipment. Biological method: Biological method utilizes the metabolic activity of microorganisms to recover precious metals from waste solar panels. This method is environmentally friendly and low-cost, but it is still in the research stage and has not yet been widely applied.

The recycling of precious metals in solar panels can not only achieve resource conservation and sustainable utilization, but also help reduce the production cost of solar products, reduce environmental pollution, and create new business opportunities.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;