Conductive silver slurry recovery_ Silver slurry recovery_ Precious metal recycling manufacturers

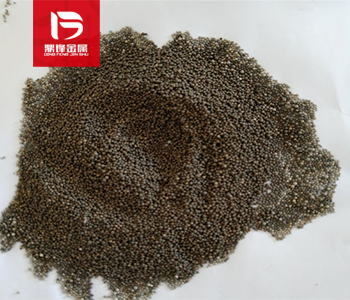

Conductive silver paste is an important material used in the manufacture of electronic components, with good conductivity and adhesion properties. It is mainly composed of conductive particles, organic solvents and thickeners, etc., and can form a uniform conductive film or coating, which is widely used in circuit boards, touch screens, solar cells and other fields. The recycling of waste conductive silver paste is one of the sources of silver-containing waste recycling. The types of silver-containing waste recycling include conductive silver paint recycling, silver mud recycling, silver contact recycling, conductive silver glue recycling, silver paste recycling, silver water recycling, etc.

Product Details

Conductive silver paste is an important material used in the manufacturing of electronic components, with good conductivity and adhesion properties. It is mainly composed of conductive particles, organic solvents, and thickeners, which can form a uniform conductive film or coating, and is widely used in fields such as circuit boards, touch screens, and solar cells.

The preparation process of conductive silver paste mainly includes the following steps: 1. Select conductive particles: conductive particles are the key components of conductive silver paste, and commonly used conductive particles include nano silver powder, silver particles and silver fibers. These conductive particles have high conductivity and good plasticity, and can form a dense conductive network during the preparation process. 2. Preparation of organic solvents: Organic solvents play a role in dissolving conductive particles and adjusting viscosity in conductive silver paste. The selection of appropriate organic solvents has a significant impact on the performance and application of conductive silver paste. Common organic solvents include butanone, di N-Methylformamide, etc. 3. Adding Thickener: Thickener is an important auxiliary agent in conductive silver slurry, used to adjust the viscosity and rheological properties of conductive silver slurry for easy coating or spraying process operations. Commonly used thickeners include polyvinyl alcohol, polyacrylic acid, etc. 4. Mixing and dispersion: Mix conductive particles, organic solvents, and thickeners according to a certain formula ratio, and perform appropriate dispersion treatment. The purpose of dispersion is to evenly disperse conductive particles in organic solvents, avoiding particle aggregation and deposition. 5. Screening and filtration: The mixed and dispersed conductive silver slurry is screened and filtered to remove particle aggregation and impurities, ensuring the quality and stability of the conductive silver slurry. 6. Adjusting viscosity: According to specific application requirements, the viscosity of conductive silver slurry can be adjusted by adding organic solvents or thickeners. The adjustment of viscosity has a significant impact on the coating performance and film forming performance of conductive silver paste. 7. Packaging and Storage: The prepared conductive silver paste needs to be packaged and stored to maintain its long-term stability and service life. Conductive silver paste is usually placed in sealed containers to avoid exposure to air and humidity. During storage, appropriate temperature and humidity should be maintained to avoid affecting the quality of conductive silver paste.

The recycling of waste conductive silver paste is one of the sources of silver containing waste recycling. The types of silver containing waste recycling include conductive silver paint recycling, silver mud recycling, silver contact point recycling, conductive silver glue recycling, silver paste recycling, silver water recycling, etc. If you have any demand for silver containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has an independent recycling and refining factory, a professional technical team, and one-on-one customer service personnel to ensure customer privacy during the recycling process.