Silver slurry recovery_ Recovery of silver containing waste liquid_ Precious metal recycling manufacturers

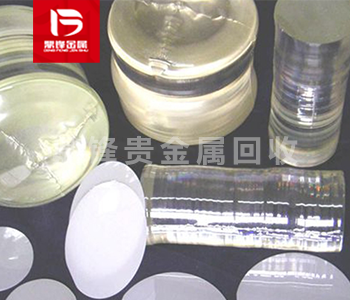

Silver paste is a colloidal solution containing high concentrations of silver particles, which has excellent electrical and thermal conductivity. It is usually composed of nano-scale silver particles, solvents and stabilizers. Silver paste is widely used in the fields of electronics, optoelectronics, energy and medicine, and is used to prepare circuit boards, conductive films, electronic devices and thermal conductive materials. The recycling of waste silver paste is one of the sources of silver-containing waste liquid recycling. Other types of silver-containing waste liquid recycling include conductive silver paint recycling, silver mud recycling, fixing water recycling, conductive silver glue recycling, conductive silver paste recycling, silver water recycling, etc.

Product Details

Silver slurry is a colloidal solution containing high concentrations of silver particles, which has excellent conductivity and thermal conductivity. It is usually composed of nanoscale silver particles, solvents, and stabilizers. Silver slurry is widely used in the fields of electronics, optoelectronics, energy, and healthcare, for the preparation of circuit boards, conductive films, electronic devices, and thermal conductive materials.

The preparation process of silver paste includes the following main steps: 1. Select the appropriate silver source: usually use silver salt as the silver source, such as silver ammonia solution, Silver nitrate, etc. These silver sources can dissolve in solvents and release silver ions that can be used to form silver particles. 2. Reduction of silver ions: By adding a reducing agent, the silver ions in the solution are reduced to nanoscale silver particles. Commonly used reducing agents include sucrose, polyols, polyethylene glycol, etc. The selection and dosage of reducing agents can affect the size and distribution of silver particles. 3. Control of particle size and dispersion: By adjusting reaction conditions and adding surfactants or dispersants, the size and dispersion of silver particles can be controlled. Surfactants can form a protective film on the surface of silver particles to prevent particle aggregation and improve the stability of the silver slurry. 4. Filtration and cleaning: After preparation, impurities and unreacted chemicals in the solvent are removed through filtration and other methods to obtain pure silver slurry.

The recycling of waste silver slurry is one of the sources of silver containing waste liquid recycling. The types of silver containing waste liquid recycling include conductive silver paint recycling, silver slurry recycling, fixing water recycling, conductive silver glue recycling, conductive silver slurry recycling, silver water recycling, etc. If you have any demand for silver containing waste liquid recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has an independent recycling and refining factory, a professional technical team, and one-on-one customer service personnel to ensure customer privacy during the recycling process.