Lithium tantalate recovery_ Tantalum lithium oxide recovery_ Rare metal recycling manufacturers

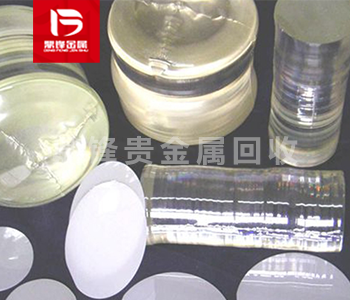

Lithium tantalate, also known as lithium tantalum acid, is a compound with the chemical formula LiTaO3. Its crystal structure belongs to the orthorhombic system and has good thermal stability and electro-oxidation properties. Lithium tantalate is widely used in the field of optical devices to manufacture components such as optical waveguides, optical modulators and electro-optical modulators. Its excellent optical properties make it one of the ideal materials for many optical devices. In addition, lithium tantalate is also used in battery technology. As one of the positive electrode materials of lithium-ion batteries, it has the characteristics of high voltage, high energy density and long cycle life. Waste lithium tantalate is one of the sources of tantalum waste recycling. Tantalum waste recycling also includes tantalum oxide recycling, tantalum carbide recycling, tantalum silicide recycling, tantalum coating recycling, tantalum nitride recycling, tantalum powder recycling, tantalum capacitor recycling, etc.

Product Details

Lithium tantalate, also known as tantalum lithium carbonate, is a compound with the chemical formula LiTaO3. Its crystal structure belongs to Orthorhombic crystal system, and has good thermal stability and electro oxidation properties. Lithium tantalate is widely used to manufacture optical waveguide, optical modulator, electro-optic modulator and other components in the field of optical devices. its excellent optical properties make it one of the ideal materials for many optical devices. In addition, Lithium tantalate is also used in battery technology as one of the cathode materials of lithium ion batteries, which has the characteristics of high voltage, high energy density and long cycle life.

There are many methods to prepare Lithium tantalate, and the following two main methods are introduced:

1. High temperature solid phase method: High temperature solid phase method is a commonly used method to prepare Lithium tantalate. First, a proper amount of tantalum powder and Lithium carbonate were mixed evenly, and calcined at high temperature. During the reaction, tantalum and lithium will react with oxygen to form Lithium tantalate. With the increase of temperature, the reaction rate accelerates and Lithium tantalate gradually forms. Finally, the product is cooled, ground and necessary post-treatment steps are carried out to obtain pure Lithium tantalate powder.

2. Solution method: solution method is another method to prepare Lithium tantalate. First, a proper amount of tantalic acid and Lithium carbonate are dissolved in a suitable solvent to prepare a solution containing tantalum and lithium. Then, under appropriate conditions, such as temperature, stirring speed and pH value, Lithium tantalate precipitation is generated through chemical reaction in the solution. The precipitate can be filtered, washed and dried to obtain pure Lithium tantalate product.

Waste Lithium tantalate is one of the sources of tantalum waste recovery. The recovery of tantalum waste includes tantalum oxide recovery, Tantalum carbide recovery, tantalum silicide recovery, tantalum coating recovery, tantalum nitride recovery, tantalum powder recovery, tantalum capacitor recovery, etc. If you have any demand for tantalum containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has its own recycling and refining factory without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.