Tantalum oxide recovery_ Tantalum catalyst recovery_ Rare metal recycling manufacturers

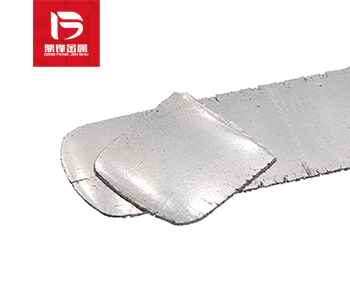

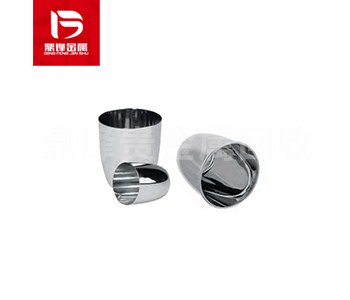

Tantalum oxide is a chemical compound consisting of tantalum and oxygen elements. Its chemical formula is Ta2O5, in which the oxidation state of tantalum is +5. Tantalum oxide has many special physical and chemical properties, making it one of the ideal materials for many industrial and scientific applications. It is a white crystalline solid with a high melting point and good chemical stability. Tantalum oxide is almost insoluble in water at room temperature, but soluble in strong alkaline solutions and strong acids such as hydrofluoric acid. Waste tantalum oxide is one of the sources of tantalum waste recycling. Tantalum waste recycling also includes tantalum silicide recycling, tantalum carbide recycling, lithium tantalum acid recycling, tantalum silicide recycling, metal tantalum recycling, tantalum nitride recycling, tantalum powder recycling, tantalum capacitor recycling, etc.

Product Details

Tantalum oxide is a chemical compound composed of tantalum and oxygen elements. Its chemical formula is Ta2O5, in which the Oxidation state of tantalum is+5. Tantalum oxide has many special physical and chemical properties, making it one of the ideal materials for many industrial and scientific applications. It is a white crystalline solid with high melting point and good chemical stability. Tantalum oxide is almost insoluble in water at room temperature, but soluble in strong alkaline solutions and strong acids such as hydrofluoric acid.

There are various methods for preparing tantalum oxide, among which the following are several commonly used preparation methods:

1. Thermal decomposition method: This is a commonly used method for preparing tantalum oxide. Firstly, tantalum metal is heated to a higher temperature to react with oxygen in the air. At high temperatures, tantalum metal reacts with oxygen to form tantalum oxide, with the main product being tantalum oxide. During this process, the morphology and crystal structure of tantalum oxide can be controlled by controlling temperature, reaction time, and atmosphere composition.

2. Solvent thermal method: Solvent thermal method is another commonly used method for preparing tantalum oxide. Firstly, choose a suitable organic solvent as the reaction medium, such as ethanol or acetone. Then, tantalum compounds such as tantalate or tantalate salts are added to the solvent and stirred to fully dissolve. Next, the reaction solution is heated to form tantalum oxide particles through hydrothermal or pyrolysis reactions. Finally, the required tantalum oxide product is obtained through steps such as filtration, washing, and drying.

Waste tantalum oxide is one of the sources of tantalum waste recycling. The recovery of tantalum waste includes tantalum silicide recovery, Tantalum carbide recovery, tantalum lithium oxide recovery, tantalum silicide recovery, metal tantalum recovery, tantalum nitride recovery, tantalum powder recovery, tantalum capacitor recovery, etc. If you have any demand for tantalum containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has its own recycling and refining factory without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.