Rhodium carbon recovery_ Rhodium carbon recovery_ Precious metal catalyst recycling manufacturer

Rhodium carbon catalyst, also known as rhodium carbon catalyst, is an important catalyst composed of rhodium and carbon. Rhodium is a precious metal with excellent catalytic performance and chemical stability. Rhodium carbon catalyst is widely used in fields such as organic synthesis and hydrogenation reaction, and has the characteristics of high efficiency, good selectivity and recyclability. Waste rhodium carbon is a recyclable source of rhodium-containing precious metal catalyst waste. The recycling of rhodium-containing precious metal catalyst waste also includes rhodium oxide recycling, rhodium chloride recycling, rhodium acetate recycling, rhodium nitrate recycling, rhodium iodide recycling, rhodium resin recycling, etc.

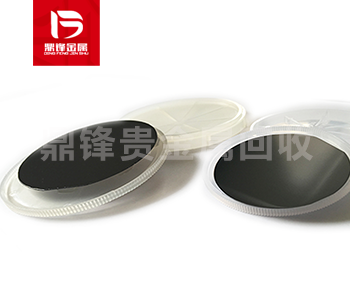

Product Details

Rhodium carbon catalyst, also known as rhodium carbon catalyst, is an important catalyst composed of rhodium and carbon. Rhodium is a precious metal with excellent catalytic performance and chemical stability. Rhodium carbon catalysts are widely used in fields such as organic synthesis and hydrogenation reactions, with high efficiency, good selectivity, and recyclability.

There are various preparation methods for rhodium carbon catalysts, and the following will introduce two common preparation methods in detail:

The first preparation method is the physical mixing method: first, the rhodium precursor (such as rhodic acid) is mixed evenly with an appropriate amount of activated carbon or other carbon carrier materials. Then, the mixture is placed in a high-temperature furnace and calcined in an inert atmosphere. During this process, the furnace temperature is usually between 400-800 degrees Celsius, and the calcination time is usually several hours. At high temperatures, the rhodium precursor is reduced to form metallic rhodium particles, which combine with the carbon carrier to form a rhodium carbon catalyst. Finally, cool the catalyst and collect it to obtain a rhodium carbon catalyst.

2. The second preparation method is chemical deposition: first, a suitable rhodium precursor (such as rhodic acid or rhodochloric acid) is dissolved in an appropriate amount of solvent to form a solution of rhodium. Then, carbon carriers such as activated carbon and Graphite oxide are added to the solution, and they are fully mixed by stirring. Next, by adding reducing agents such as ethylene glycol, methanol, etc., the rhodium precursor is reduced to metallic rhodium. The reduction reaction is carried out at an appropriate temperature and time, usually for several hours at room temperature. After the reduction reaction is completed, the catalyst is separated from the solution and washed, dried, and other steps are taken to obtain a rhodium carbon catalyst.

Waste rhodium carbon is a recyclable source of rhodium containing precious metal catalyst waste. The recovery of rhodium containing precious metal catalyst waste includes rhodium oxide recovery, rhodium chloride recovery, rhodium acetate recovery, Rhodium(III) nitrate recovery, rhodium iodide recovery, rhodium resin recovery, etc. If you have any demand for rhodium containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has its own recycling and refining factory without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.