Electrolytic Rhodium Recovery_ Rhodium plating recycling price_ Precious metal recycling and refining manufacturers

Electrolytic rhodium is a technology that separates rhodium from compounds. Rhodium is a rare precious metal with high density, high melting point and good corrosion resistance. It is widely used in electronics, aerospace, chemistry and medicine. Waste rhodium-plated products are one of the sources of rhodium waste recycling. The sources of rhodium waste recycling include rhodium block recycling, rhodium slag recycling, rhodium water recycling, rhodium slurry recycling, rhodium rod recycling, rhodium gold recycling, etc. If you have any needs for recycling rhodium-plated rhodium-containing waste, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has an independent recycling and refining factory without middlemen to make a profit from the price difference. There is no middleman to make a profit from the price difference. Professional technical team and customer service staff provide one-to-one service, and customer privacy is guaranteed during the recycling process.

Product Details

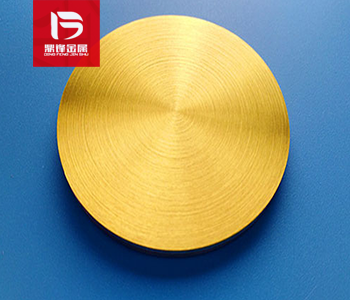

Electrolytic rhodium is a technique for separating rhodium from compounds. Rhodium is a rare precious metal with high density, high melting point, and good corrosion resistance. It has extensive applications in fields such as electronics, aerospace, chemistry, and medicine. However, due to its rare and expensive nature, its market value is relatively high. The process of electrolysis of rhodium involves reducing ions in a rhodium salt solution to pure rhodium metal. This process needs to be carried out at high temperatures, as high temperatures help improve the efficiency of electrolytic reactions. At the same time, it is necessary to use a solvent that can conduct electricity so that electrons can flow in the solvent and react in a rhodium salt solution. Common conductive solvents include metals such as platinum, silver, gold, copper, and palladium.

The main advantage of electrolytic rhodium is that it can produce high-purity rhodium metal. This high-purity rhodium can be used to prepare other chemicals, such as rhodium catalysts and fuel cells. In addition, electrolytic rhodium can also be used to recover rhodium from waste, thereby saving resources and reducing environmental pollution. However, the process of electrolysis of rhodium also has some drawbacks. Firstly, it requires high temperature and high energy consumption, which makes its cost higher. Secondly, the production of electrolytic rhodium requires a large amount of electricity and chemicals, which will generate a large amount of waste and pollutants. Therefore, before conducting electrolysis of rhodium, it is necessary to evaluate and plan for environmental and energy consumption to ensure its sustainability and environmental friendliness.

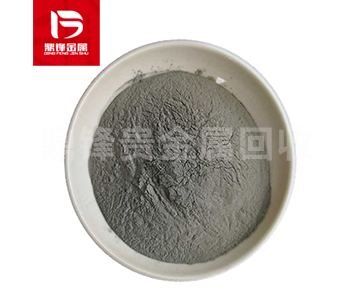

Waste rhodium plating products are one of the sources of rhodium waste recycling, which includes rhodium block recycling, rhodium slag recycling, rhodium water recycling, rhodium slurry recycling, rhodium rod recycling, rhodium gold recycling, etc. If you have any demand for the recycling of rhodium plating and rhodium containing waste, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has its own recycling and refining factory, and there is no profit difference between intermediaries. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.