Recycling Rhodium Scraps: A Path to Sustainability and Value Retention

Recycling rhodium scraps is an essential practice for industries seeking to balance economic needs with environmental stewardship. It supports sustainable growth by reducing reliance on mining and promoting a circular economy. As technology advances, recycling processes will become even more efficient, ensuring a steady supply of rhodium to meet the demands of the future.

Product Details

Rhodium is a rare and highly valuable metal, prized for its unique chemical properties and critical applications in industries such as automotive, electronics, and jewelry. However, its rarity and the environmental toll of mining make recycling rhodium scraps a sustainable and economically viable alternative. Recycling not only helps conserve natural resources but also supports a circular economy by recovering this indispensable metal for reuse.

Why Recycling Rhodium is Crucial

The importance of recycling rhodium lies in its scarcity and the growing demand across industries. Rhodium is primarily a byproduct of platinum and nickel mining, which limits its availability. As industries strive to meet stricter environmental regulations and adopt sustainable practices, recycled rhodium offers a reliable solution for maintaining supply without increasing environmental harm.

Sources of Rhodium Scraps

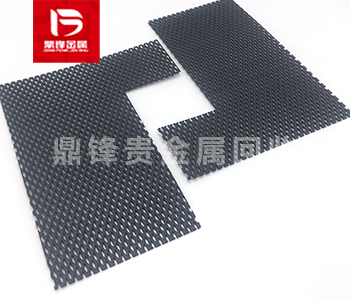

Recycling rhodium scraps involves recovering the metal from various sources, including:

- Catalytic Converters: These automotive components are the largest source of rhodium scraps, containing significant amounts of the metal used to reduce vehicle emissions.

- Jewelry: Rhodium-plated jewelry items, known for their reflective shine and durability, are another valuable source.

- Industrial Equipment: High-performance items like thermocouples, crucibles, and glass manufacturing tools often contain rhodium.

- Electronics: Rhodium's conductivity and corrosion resistance make it essential for electrical contacts and connectors.

Recycling Techniques

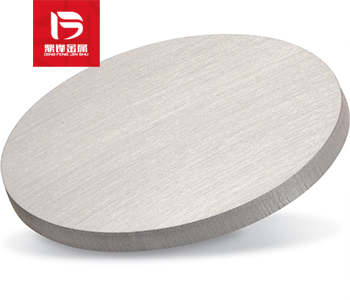

Recovering rhodium from scraps requires advanced recycling techniques to ensure efficiency and purity:

- Hydrometallurgical Processes: Acid-based methods dissolve rhodium, enabling separation from other metals.

- Pyrometallurgical Methods: High-temperature processes melt and refine materials to extract rhodium.

- Electrochemical Recovery: Electrolysis isolates rhodium from industrial residues with high precision.

Economic and Environmental Benefits

Recycling rhodium is both economically advantageous and environmentally responsible:

- Economic Value: The high market price of rhodium makes recycling financially lucrative, providing industries with cost-effective access to the metal.

- Resource Conservation: Recycling reduces the need for mining, preserving finite natural reserves.

- Environmental Impact: By recycling rhodium, industries minimize carbon emissions and waste generation, aligning with global sustainability goals.

Recycling rhodium scraps is an essential practice for industries seeking to balance economic needs with environmental stewardship. It supports sustainable growth by reducing reliance on mining and promoting a circular economy. As technology advances, recycling processes will become even more efficient, ensuring a steady supply of rhodium to meet the demands of the future.

Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price.

Email us with pictures at dfpmr5719@dfpmr.com or send us on whatsapp at +8613760175719 to discuss your materials. We provide professional evaluations of industrial precious metal-bearing scrap and estimates of precious metal content.