Recycling Rhodium Waste: Turning Industrial Residue into Valuable Resources

Rhodium, one of the six platinum group metals (PGMs), is among the rarest and most expensive elements in the world. Its unique physical and chemical properties make it essential in modern industries, particularly in automotive emission control, jewelry, chemical processing, and glass manufacturing. However, because rhodium is scarce and expensive to mine, industries are increasingly turning to recycling rhodium waste as a sustainable and cost-effective solution.

Product Details

Rhodium, one of the six platinum group metals (PGMs), is among the rarest and most expensive elements in the world. Its unique physical and chemical properties make it essential in modern industries, particularly in automotive emission control, jewelry, chemical processing, and glass manufacturing. However, because rhodium is scarce and expensive to mine, industries are increasingly turning to recycling rhodium waste as a sustainable and cost-effective solution.

At Dingfeng Precious Metals, we specialize in the recovery and refining of rhodium from industrial waste, ensuring that companies maximize returns while supporting environmental responsibility.

Why Rhodium Is So Valuable

Rhodium’s value is driven by its combination of rarity and utility:

Exceptional corrosion resistance: Rhodium is virtually immune to tarnishing, making it ideal for protective coatings.

High reflectivity: Its bright, silvery appearance is prized in jewelry and optical applications.

Catalytic efficiency: Rhodium is one of the most effective catalysts for reducing nitrogen oxides in automotive exhaust.

High melting point: At 1,964°C, rhodium can withstand extreme temperatures, making it indispensable in specialized industrial equipment.

With annual mine production measured only in a few tons, recycling rhodium waste is critical to meeting global demand.

Common Sources of Rhodium Waste

Rhodium waste is generated across many industries, often in concentrated forms that make it ideal for recycling. The most common sources include:

Automotive catalytic converters: Contain significant amounts of rhodium along with platinum and palladium.

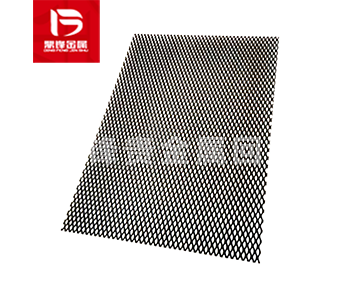

Electroplating waste: Rhodium-plated jewelry and the residues from plating baths.

Chemical catalysts: Spent rhodium catalysts used in producing acetic acid, nitric acid, and other chemicals.

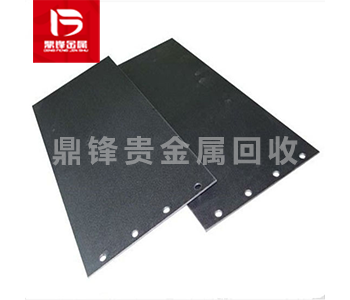

Glass manufacturing equipment: Rhodium alloys used in crucibles and components exposed to molten glass.

Laboratory equipment: Thermocouples, crucibles, and other specialized tools made with rhodium alloys.

Each of these waste streams offers an opportunity to recover rhodium that can be reintroduced into the supply chain.

The Recycling Process

Recycling rhodium waste requires precision and advanced metallurgical expertise. At Dingfeng Precious Metals, our recycling process involves:

Material Assessment

Samples are analyzed to determine rhodium content and overall value.Sorting and Pre-Treatment

Waste is separated and cleaned to remove contaminants and non-precious elements.Smelting

Materials are processed in high-temperature furnaces to separate rhodium and other precious metals from base materials.Chemical Refining

Specialized chemical techniques are used to isolate rhodium, which is resistant to many common acids and requires advanced refining methods.Purification

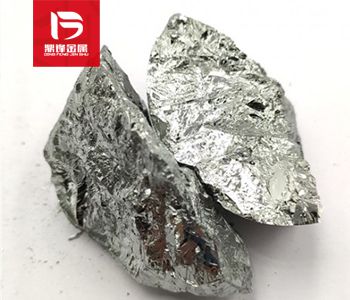

Recovered rhodium is refined to high purity, typically 99.9% or greater, making it suitable for reuse in demanding industrial applications.

Benefits of Recycling Rhodium Waste

Recycling rhodium is not just about recovering value—it provides multiple strategic advantages:

Economic returns: Companies can recover significant value from spent materials, especially given rhodium’s high market price.

Supply chain security: Recycling reduces dependence on limited global mining sources.

Environmental responsibility: Recycling consumes less energy and causes less environmental damage compared to mining.

Sustainability: Recycling ensures that rhodium, a finite resource, is preserved for future generations.

Dingfeng Precious Metals: Your Reliable Partner

At Dingfeng Precious Metals, we offer professional rhodium recycling services backed by years of expertise in the precious metals industry. Our services include:

Accurate metal content analysis to provide fair and transparent settlements.

Advanced refining technology that ensures high recovery rates.

Secure material handling, protecting clients’ valuable assets.

Global service reach, helping clients worldwide recycle their rhodium waste efficiently.

Whether your company operates in automotive, chemical, jewelry, or glass production, Dingfeng Precious Metals delivers customized recycling solutions to meet your needs.

Rhodium is far too rare and valuable to discard. Recycling rhodium waste ensures that industries recover critical resources, reduce costs, and contribute to a more sustainable global economy. With the expertise of Dingfeng Precious Metals, companies can transform industrial residue into high-purity rhodium ready for reuse in essential applications.

For professional rhodium recycling solutions, contact us at dfpmr5719@dfpmr.com or WhatsApp +8613760175719.