Tantalum alloy recycling_ Metal tantalum recovery_ Rare metal recycling manufacturers

Tantalum alloy is a material formed by alloying tantalum and other metal elements. Tantalum is a rare and precious transition metal with a high melting point, excellent chemical stability and corrosion resistance, and outstanding mechanical properties. Tantalum alloys are widely used in aerospace, electronics, chemical and medical fields to meet special requirements such as high temperature, corrosion and high strength. Scrap tantalum alloy is one of the sources of tantalum-containing waste recycling. Tantalum-containing waste recycling also includes tantalum capacitor recycling, tantalum wire recycling, tantalum sheet recycling, tantalum block recycling, tantalum needle recycling, tantalum rod recycling, tantalum tube recycling, tantalum pellet recycling, etc.

Product Details

Tantalum alloy is a material made by alloying tantalum with other metallic elements. Tantalum is a rare and precious transition metal with high melting point, excellent chemical stability, corrosion resistance, and excellent mechanical properties. Tantalum alloys are widely used in aerospace, electronics, chemical, and medical fields to meet special requirements such as high temperature, corrosion, and high strength.

The production of tantalum alloy involves multiple steps, mainly including the following stages:

1. Extraction and refining of tantalum: tantalum generally exists in the form of ores, such as Tantalite and tantalum niobium ore. Firstly, the ore undergoes processing steps such as ore beneficiation and crushing to obtain a tantalum containing concentrate. Then, through chemical treatment and smelting methods, the concentrate is converted into tantalum compounds such as tantalum acid and tantalum chloride. Finally, the tantalum compound is reduced to pure tantalum through a reduction reaction or electrolysis.

2. Alloying: Alloying pure tantalum with other metal elements to improve its performance and meet specific needs. Common alloying elements include niobium, tungsten, copper, iron, etc. The methods of alloying include melting, powder metallurgy, and chemical vapor deposition. By controlling the content and proportion of alloying elements, the hardness, strength, corrosion resistance, and thermal stability of tantalum alloys can be adjusted.

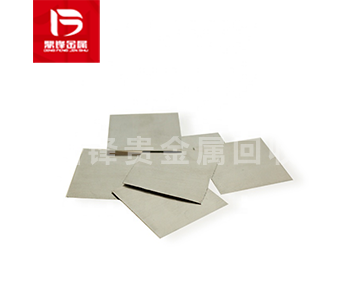

3. Hot working and forming: Tantalum alloys are usually prepared in the form of billets, and then formed by Hot working and forming processes. Hot working includes hot rolling, forging and extrusion, which are used to change the shape and size of tantalum alloys. The forming process involves cutting, welding, and surface treatment to manufacture various shapes of tantalum alloy products, such as plates, pipes, wires, and parts.

4. Precision machining and surface treatment: Further processing and improvement of tantalum alloy through precision machining and surface treatment. Precision machining includes processes such as drilling, milling, grinding, and polishing to improve the accuracy and smoothness of tantalum alloy products. Surface treatment can include pickling, electrochemical polishing, and oxidation to improve the surface performance and corrosion resistance of tantalum alloys.

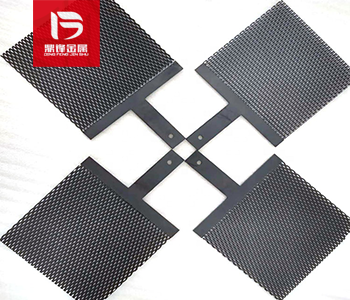

Waste tantalum alloys are one of the sources of tantalum containing waste recycling, including tantalum capacitor recycling, tantalum wire recycling, tantalum sheet recycling, tantalum block recycling, tantalum needle recycling, tantalum rod recycling, tantalum tube recycling, tantalum particle recycling, etc. If you have any demand for tantalum containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has its own recycling and refining factory without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.