Tantalum ingot recovery_ Tantalum block recovery_ Rare metal recycling manufacturers

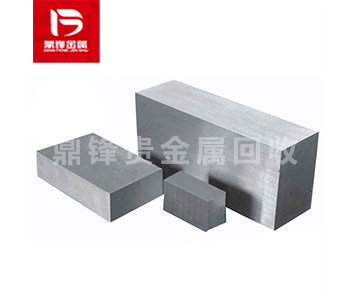

Tantalum ingot is a metal block made of pure tantalum. Tantalum is a rare metal with a high melting point, corrosion resistance and good electrical conductivity. It is one of the elements with very low content in the earth's crust, so the tantalum used in industry is mainly extracted from tantalum ore through processes such as mining and smelting. Scrap tantalum ingots are one of the sources of tantalum-containing waste recycling. Tantalum-containing waste recycling also includes tantalum capacitor recycling, tantalum wire recycling, tantalum sheet recycling, tantalum tube recycling, tantalum alloy recycling, tantalum rod recycling, tantalum powder recycling, tantalum pellet recycling, etc.

Product Details

Tantalum ingot is a metal block made of pure tantalum. Tantalum is a rare metal with high melting point, corrosion resistance, and good conductivity. It is one of the elements with very low content in the crust, so tantalum used in industry is mainly extracted from tantalum ore through mining and smelting processes.

The production process of tantalum ingots mainly includes the following steps:

1. Mining: The main ore of tantalum is tantalum niobium ore, also known as tantalum niobium titanium ore. This type of ore usually exists in the Earth's crust and needs to be extracted through processes such as mining and ore beneficiation. Tantalum niobium ore usually contains other metallic elements, such as niobium and titanium.

2. Refining: Tantalum extracted from ore needs to undergo a refining process to remove other impurities and metal elements. This process usually includes steps such as crushing, grinding, flotation, and magnetic separation to obtain high-purity tantalum.

3. Acid leaching: Refined tantalum usually exists in the form of powder or fragments. In order to further improve the purity of tantalum, these tantalum powders need to undergo an acid leaching process. Acid leaching usually uses strong acids such as hydrofluoric acid or sulfuric acid to dissolve impurities on the surface of tantalum.

4. Fluoride conversion: the tantalum powder after acid leaching reacts with hydrogen fluoride or Sodium fluoride to form tantalum chloride. This process is usually carried out at high temperatures.

5. Reduction: Tantalum chloride is reduced by heating to convert it into metallic tantalum. This process is usually carried out in an inert atmosphere to avoid reactions between tantalum and oxygen in the air.

6. Tantalum ingot preparation: The reduced metal tantalum can be prepared into tantalum ingots through melting and casting methods. During the melting process, tantalum is usually alloyed with other metals to improve its properties. The most common alloy is tantalum niobium alloy, which has higher strength and corrosion resistance.

7. Processing and finishing: The prepared tantalum ingot can be processed and finished in various ways to obtain the desired shape and size. This includes processes such as forging, rolling, stretching, cutting, as well as further heat treatment and surface treatment.

Waste tantalum ingots are one of the sources of tantalum containing waste recycling, including tantalum capacitor recycling, tantalum wire recycling, tantalum sheet recycling, tantalum tube recycling, tantalum alloy recycling, tantalum rod recycling, tantalum powder recycling, tantalum particle recycling, etc. If you have any demand for tantalum containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has its own recycling and refining factory without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.