Why Iridium-Coated Titanium Mesh is a Rare & Valuable Material

By recognizing the exceptional value of iridium-coated titanium mesh, engineers, scientists, and investors can capitalize on one of the world’s most sought-after advanced materials.

Product Details

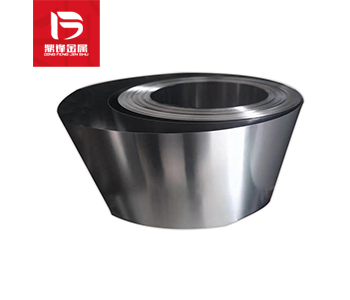

Iridium is one of the rarest and most corrosion-resistant metals on Earth—three times rarer than gold—and its unique properties make it indispensable in high-tech industries. When coated onto titanium mesh, it creates an ultra-durable, high-performance material used in rocket engines, medical implants, and advanced chemical processing.

For engineers, scientists, and investors in rare metals, understanding the value of iridium-coated titanium mesh is key to recognizing its potential in both industrial applications and high-value scrap recovery.

Iridium: The Rarest Industrial Metal

Extreme scarcity – Annual global iridium production is only 7-10 tons, compared to ~3,000 tons of gold.

Unmatched corrosion resistance – Even at high temperatures, iridium resists acids, alkalis, and oxidation.

Critical for aerospace & medicine – Used in rocket engine nozzles, deep-sea equipment, and cancer treatment devices.When applied as a coating on titanium mesh, iridium enhances its durability while maintaining lightweight properties, making it ideal for extreme environments.

Key Applications of Iridium-Coated Titanium Mesh

1. Space & Rocket Technology

Used in thruster components and fuel injectors due to its ability to withstand extreme heat and chemical erosion.

Essential for satellite propulsion systems, where material failure is not an option.

2. Medical & Surgical Implants

Iridium’s biocompatibility makes it ideal for pacemaker electrodes and neurostimulation devices.

Used in radiation therapy components for precise cancer treatment.

3. Advanced Electrochemistry

Proton Exchange Membrane (PEM) electrolyzers rely on iridium-coated titanium for efficient hydrogen production.

Critical in chlor-alkali processing, where corrosion resistance is vital.

Why Recycling Iridium-Coated Titanium is Crucial

Given iridium’s scarcity, recovering it from scrap is both economically and environmentally essential.

Best Practices for Iridium Recovery

XRF Testing – Confirms iridium content before processing.

Chemical Leaching – Dissolves the coating without damaging the titanium substrate.

Electrolytic Recovery – Efficiently extracts pure iridium from scrap.

Since iridium prices can exceed $5,000 per ounce, even small amounts recovered from scrap can yield significant returns.

Investing in Iridium: A Strategic Opportunity

With growing demand in green energy (hydrogen fuel cells) and space exploration, iridium’s value is projected to rise. Investors and industrial buyers should consider:

Stockpiling high-quality scrap for future refining.

Partnering with specialized refiners to maximize recovery rates.

Tracking market trends in aerospace and clean tech sectors.

Unlock the Hidden Value in Your Scrap

If you work with iridium plating, high-value titanium scrap, or corrosion-resistant metals, don’t let this rare resource go to waste. Professional recovery ensures maximum returns from space-grade materials and industrial byproducts.

Contact us today for expert iridium refining and recycling solutions!

SEO Keywords: iridium plating, high-value titanium scrap, corrosion-resistant metals, space-grade materials, iridium recovery, rare metal investing, titanium mesh recycling.

By recognizing the exceptional value of iridium-coated titanium mesh, engineers, scientists, and investors can capitalize on one of the world’s most sought-after advanced materials.