Silver solder paste recycling_ Silver flux recycling price_ Precious metal recycling and refining manufacturers

Silver solder paste is a popular name or term. There are two types of products: one is silver flux, which does not contain silver. It is a non-metallic substance used with silver solder to play a reducing role. It is generally composed of boric acid and boric acid compounds, and is in a white paste. The national standard brand is: flux 102 or QJ102. The other type refers to paste silver solder, which contains silver. This type of product can be used directly for brazing. The ingredients include three parts: ultra-fine metal silver solder particles, flux (that is, QJ102 mentioned just now), and binder. Commonly used paste silver solders are Ruilite HG-45 and HG-60, whose metal silver content reaches 45% and 60%.

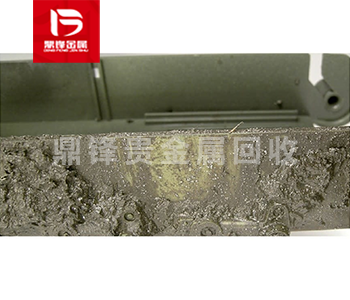

Product Details

Silver solder paste is a common term or term. There are two types of products: one refers to silver flux, which does not contain silver, and is a non-metallic substance used in conjunction with silver solder to have a reducing effect. It is generally composed of boric acid and boric acid compounds, in a white paste form, with a national standard grade of flux 102 or QJ102. Another type refers to paste silver solder, which contains silver. This type of product can be directly brazed and consists of three parts: ultrafine metal silver solder particles, flux (also known as QJ102), and binder. The commonly used paste silver solders, Ruili Te HG-45 and HG-60, have a metal silver content of 45% and 60%.

Silver solder paste contains a mixture of silver, copper, and zinc, which gives it unique properties. The silver content makes the solder strong and durable, while copper and zinc improve the bonding and melting properties of the mixture. One of the advantages of using silver solder paste is that it forms a stronger bond than regular solder. It is also unlikely to fail under pressure, vibration, or temperature changes. Silver solder paste is also more corrosion-resistant than other types of solder, making it very suitable for use in harsh or corrosive environments, such as marine or industrial environments. Another advantage of using silver solder paste is that it is more tolerant than other types of solder. Due to its consistency in paste, it can fill gaps, make it easier to use, and produce cleaner and more precise bonding.

Waste silver solder paste is one of the sources of silver containing waste recycling. The types of silver containing waste recycling include silver slurry recycling, silver mud recycling, silver water recycling, silver wiping cloth recycling, conductive silver slurry recycling, silver electrode recycling, etc. If you have any demand for silver containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has an independent recycling and refining factory, a professional technical team, and one-on-one customer service personnel to ensure customer privacy during the recycling process.