The Journey of Recycled Spark Plugs and the Versatile Applications of Recovered Metals

Spark plugs, essential components in internal combustion engines, are more than just ignition tools—they are treasure troves of precious Platinum Group Metals (PGMs) like platinum, iridium, and palladium. These metals are prized for their durability, high melting points, and electrical conductivity. Recycling spark plugs not only conserves these scarce resources but also mitigates the environmental toll of mining. Let’s explore where these recycled metals find new life and their role in driving sustainability.

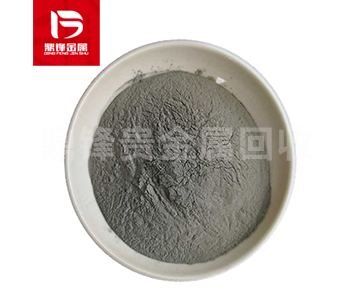

Product Details

Spark plugs, essential components in internal combustion engines, are more than just ignition tools—they are treasure troves of precious Platinum Group Metals (PGMs) like platinum, iridium, and palladium. These metals are prized for their durability, high melting points, and electrical conductivity. Recycling spark plugs not only conserves these scarce resources but also mitigates the environmental toll of mining. Let’s explore where these recycled metals find new life and their role in driving sustainability.

Automotive Industry: Closing the Loop

Recycled PGMs from spark plugs often return to their roots. In catalytic converters, they transform harmful emissions into less toxic gases, playing a critical role in reducing vehicle pollution. Additionally, manufacturers reuse recovered iridium and platinum to produce high-performance spark plugs, creating a circular economy. This reduces reliance on virgin materials, lowering both costs and environmental impact.

Telecommunications: Powering Connectivity

The rollout of 5G technology demands robust, efficient components. Recycled PGMs are integral to RF connectors and circuit boards in 5G infrastructure, ensuring reliable signal transmission and durability. Their resistance to corrosion and high-temperature stability makes them ideal for the demanding environments of telecom equipment.

Electronics: Miniaturization Meets Sustainability

In electronics, PGMs are vital for motherboards, hard drive connectors, and memory chips. As devices shrink, the need for reliable, high-conductivity materials grows. Recycled PGMs meet this demand, enabling the production of compact, high-performance devices while aligning with eco-friendly manufacturing practices.

Healthcare: Lifesaving Innovations

The biocompatibility and corrosion resistance of PGMs make them indispensable in healthcare. Recycled metals from spark plugs are refined to medical-grade standards for use in pacemakers, dental implants, and surgical tools. This not only supports advanced medical care but also ensures ethical sourcing of critical materials.

Global Reuse: A World of Applications

The journey of recycled PGMs spans continents. For instance, iridium recovered in North America might be shipped to Japan for precision electronics, such as semiconductor coatings or aerospace sensors. In Europe, it could be reforged into remanufactured spark plugs or automotive sensors, showcasing the global interdependence of recycling and manufacturing.

Sustainability and ESG: Tracking Impact

Corporations increasingly leverage recycled PGMs to meet Environmental, Social, and Governance (ESG) targets. By integrating recycled metals, companies reduce carbon footprints—recycling PGMs consumes significantly less energy than mining—and enhance supply chain transparency. Sustainability reports often highlight the percentage of recycled content, aligning with frameworks like the Global Reporting Initiative (GRI) to attract eco-conscious investors and comply with regulations.

Conclusion

Recycling spark plugs transforms discarded components into valuable resources, fueling industries from automotive to healthcare. This process not only supports technological advancement but also propels the global shift toward a circular economy. As industries prioritize sustainability, the reuse of PGMs exemplifies how innovation and environmental stewardship can go hand in hand, sparking a cleaner, greener future.