From Scrap to Shine – How We Recover Gold from Plated Items

In cases where electroplated materials are involved, we use electrolysis to separate and deposit gold ions into a purified form. 5. Refining and Quality Control Recovered gold is refined to high purity (up to 99.99%) using processes like aqua regia or Miller/ Wohlwill refining. It’s then assayed and delivered in the form requested by the customer—powder, flakes, or bullion.

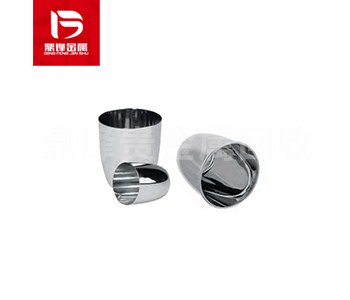

Product Details

Gold recovery from plated items is a specialized process that requires deep technical knowledge and state-of-the-art equipment. Here's a closer look at our multi-step recovery process at Dingfeng Precious Metals:

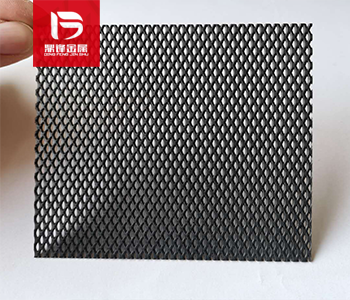

1. Inspection and Sorting

We begin by classifying materials based on their composition—whether it's gold-plated pins, PCB boards, connectors, or jewelry. Accurate categorization ensures optimized processing.

2. Mechanical Separation

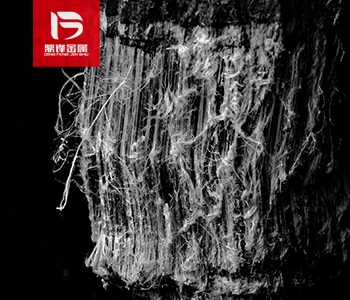

Items are stripped of plastic, ceramic, or other non-metallic parts through mechanical shredding or manual disassembly.

3. Chemical Treatment

Using environmentally controlled chemical stripping or leaching methods, we dissolve base metals such as copper or nickel, isolating the thin gold plating. We strictly manage waste treatment to avoid environmental harm.

4. Electrolytic Recovery

In cases where electroplated materials are involved, we use electrolysis to separate and deposit gold ions into a purified form.

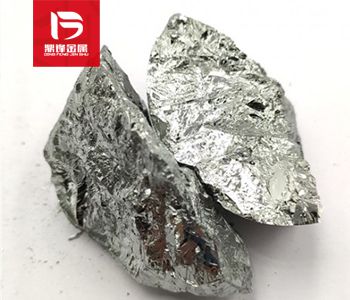

5. Refining and Quality Control

Recovered gold is refined to high purity (up to 99.99%) using processes like aqua regia or Miller/ Wohlwill refining. It’s then assayed and delivered in the form requested by the customer—powder, flakes, or bullion.

Our facility complies with strict environmental and safety standards, ensuring every gram of gold is recovered responsibly and efficiently.