Maximize Your Returns with Professional Iridium Recycling Services

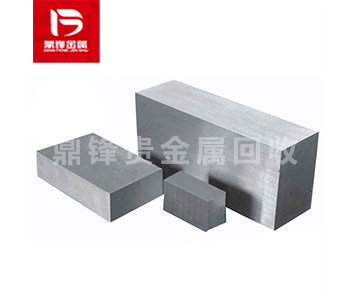

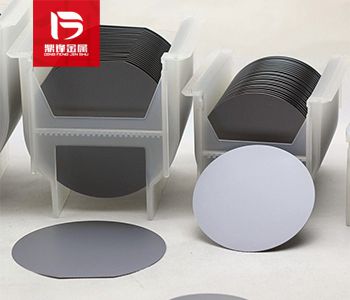

Product Details

Why Choose Dingfeng for Iridium Recycling?

1. Industry-Leading Recovery Rates

Our proprietary hydrometallurgical refining technology achieves:

- 92-99% recovery rates from complex scrap materials

- 99.95% purity meeting ASTM B684 standards

- Zero wastewater discharge (closed-loop processing)

"After testing 3 refiners, Dingfeng delivered 11% higher yields from our spent catalysts than competitors."

— Dr. Chen, Materials Director at GreenHydrogen Solutions

2. Fully Certified & Transparent Process

- ISO 9001 & 14001 certified quality/environmental systems

- Responsible Minerals Initiative (RMI) compliant

- LBMA-accredited assay laboratory

- Live refinery monitoring via 24/7 camera feed for clients

3. Highest Payouts in the Industry

We offer:

98% of LME spot price for qualified materials

Price-lock guarantees for large shipments

Same-day electronic payments upon assay approval

What Iridium Scrap Do We Accept?

We process all iridium-bearing materials with specialized recovery methods for each type:

Scrap Type Iridium Content Common Sources Spark plug electrodes 0.1-0.3g per unit Automotive/aerospace maintenance Laboratory crucibles 99.8% pure Semiconductor/CVD production Chemical catalysts 3-15% iridium Pharma/PET plastic manufacturing Electroplating sludge 0.5-8% recoverable Electronics finishing waste X-ray machine parts 95%+ purity Medical equipment decommissioning Our 3-Step Recycling Process

Step 1: Free Material Evaluation

- Email photos/specs to our metallurgists

- Receive binding quote within 1 business day

- Optional on-site XRF testing for 100kg+ lots

Step 2: Secure Logistics

- Pre-paid shipping labels for continental Asia

- Insured armored transport for high-value loads

- Customs clearance support for international shipments

Step 3: Fast Payment

- Assay completed within 48 hours of receipt

- Funds transferred via SWIFT/Wire/WeChat Pay

- Detailed materials recovery report provided