The Environmental and Economic Case for Germanium Recycling in the Electronics Industry

The electronics manufacturing sector generates significant amounts of germanium-containing waste that often goes unrecognized. This article examines why responsible germanium recovery makes both ecological and financial sense for device producers.

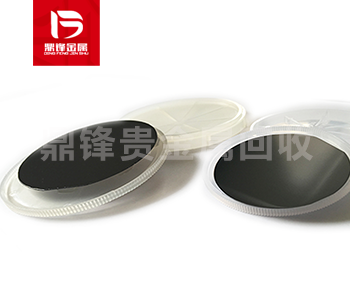

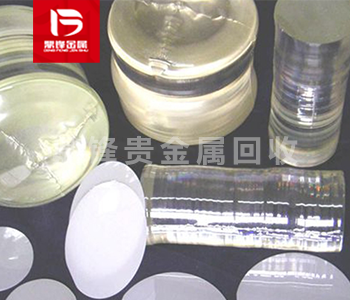

Product Details

The electronics manufacturing sector generates significant amounts of germanium-containing waste that often goes unrecognized. This article examines why responsible germanium recovery makes both ecological and financial sense for device producers.

The Hidden Costs of Germanium Waste

Most manufacturers underestimate their germanium losses through:

- Process scrap: Up to 15% material loss in semiconductor fabrication

- Obsolete inventory: Legacy components containing germanium

- Maintenance byproducts: Chamber cleanings and tool servicing waste

A 2023 study by the International Electronics Manufacturing Initiative found:

- Only 32% of potential germanium scrap gets recovered

- The average fab loses $350,000 annually in unrecovered germanium

- Recycling can reduce Scope 3 emissions by 8-12% for optics manufacturers

Dingfeng's Electronics-Specific Solutions

We've developed specialized approaches for electronics waste:

For Semiconductor Manufacturers:

- Closed-loop recycling programs for test wafers

- Sludge recovery from CMP processes

- Germanium reclamation from epitaxial growth byproducts

For EMS Providers:

- X-ray sorting of mixed electronic scrap

- Selective leaching of germanium from board assemblies

- High-yield recovery from connector plating baths

Technical Innovation: Our patented Ge-X9 process achieves 98.5% recovery from complex e-waste streams while maintaining >99.99% purity standards required for semiconductor reuse.

Implementation Roadmap

Waste Characterization (2-4 weeks):

- On-site sampling and analysis

- Waste stream mapping

- Recovery potential assessment

Pilot Program (8-12 weeks):

- Small-scale processing

- Quality verification

- Economic modeling

Full Deployment:

- Customized collection systems

- Staff training

- Continuous improvement protocols

Case Example: A Taiwanese foundry reduced virgin germanium purchases by 40% after implementing our full-scrap recovery system, achieving ROI in 11 months.

Next Steps: Download our "Germanium Recovery for Electronics Manufacturers" whitepaper or schedule a facility assessment.