Iridium carbon recovery_ Iridium carbon recovery_ Precious metal catalyst recycling manufacturer

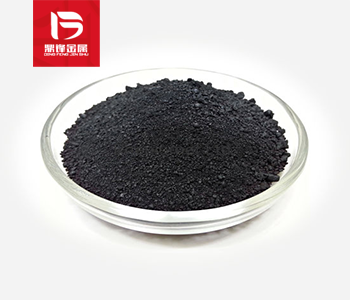

Iridium carbon is a special chemical substance composed of iridium and carbon elements. Iridium is a precious metal belonging to the platinum group, which has the characteristics of high density, high melting point and corrosion resistance. Carbon is a non-metallic element and one of the most common elements on earth. Iridium carbon has a wide range of applications in many fields, including electronics, materials science and catalysts. Waste iridium carbon is one of the sources of recycling of iridium-containing precious metal catalyst waste. The recycling of iridium-containing precious metal catalyst waste also includes chloroiridic acid recovery, iridium chloride recovery, iridium salt recovery, iridium acetate recovery, iridium oxide recovery, iridium bromide recovery, etc.

Product Details

Iridium carbon is a special chemical substance composed of iridium and carbon elements. Iridium is a precious metal belonging to the platinum series element, characterized by high density, high melting point, and corrosion resistance. Carbon is a non-metallic element and one of the most common elements on Earth. Iridium carbon has extensive applications in many fields, including electronics, materials science, and catalysts.

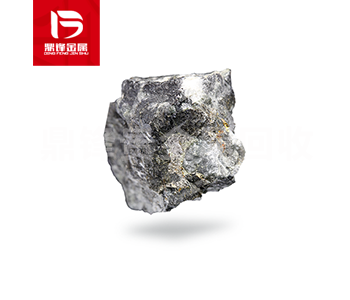

The preparation of iridium carbon requires a series of chemical reactions and processing steps. The following is a detailed introduction to the preparation process of iridium carbon: 1. Iridium extraction: Firstly, iridium metal is extracted from iridium ore or waste. The extraction process of iridium usually involves steps such as chemical dissolution, filtration, and reduction. These steps aim to separate and purify iridium metal. 2. Preparation of iridium carbon: Once pure iridium metal is obtained, the preparation of iridium carbon can begin. The most commonly used method is to mix iridium with carbon powder and heat it to high temperature. At high temperatures, carbon reacts with iridium to form iridium carbides. 3. Reaction conditions: The preparation of iridium carbon is usually carried out in a vacuum or inert atmosphere to avoid reaction with oxygen or other impurities in the air. During the preparation process, iridium metal and carbon powder are mixed in a certain proportion and heated in a high-temperature furnace. 4. Furnace temperature time: The heating process requires controlling the furnace temperature time to ensure that iridium and carbon fully react and form iridium carbon. Usually, the temperature is above 2000 degrees Celsius and the reaction time is several hours. 5. Cooling and cleaning: Once the reaction is completed, it is necessary to cool the reactant and remove unreacted carbon powder and other impurities. Cleaning treatment can be carried out through methods such as acid washing and water washing to obtain pure iridium carbon products.

Waste iridium carbon is one of the sources of recycling precious metal catalyst waste containing iridium. The recycling of precious metal catalyst waste containing iridium also includes the recycling of chloroiridium acid, iridium chloride, iridium salt, iridium acetate, iridium oxide, iridium bromide, etc. If you have any demand for iridium containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has its own recycling and refining factory without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.