The Critical Role of Iridium Recycling in Sustainable Industry Practices

As industries prioritize circular economy models, iridium recycling will gain prominence. Innovations in nanotechnology and urban mining—extracting metals from e-waste—will further enhance recovery rates. Governments and corporations are already incentivizing closed-loop systems to align with ESG (Environmental, Social, Governance) goals. Iridium recycling is not merely a technical process but a necessity for sustainable industrial growth. By transforming waste into valuable resources, we safeguard both economic resilience and ecological balance for future generations.

Product Details

Iridium, one of the rarest and most corrosion-resistant metals on Earth, plays a vital role in advanced industrial applications. As global demand for high-performance materials grows, iridium recycling has emerged as a cornerstone of sustainable resource management. This precious metal is indispensable in sectors such as electronics, automotive manufacturing, chemical catalysis, and medical technology, making its recovery not just economically valuable but environmentally essential.

Key Applications Driving Iridium Demand

Iridium's exceptional properties—including its high melting point (2,447°C), resistance to extreme environments, and catalytic efficiency—make it irreplaceable in critical technologies. For instance, it is used in:

Spark plugs and aircraft engine components for durability under high temperatures.

Electrolysis cells for green hydrogen production, supporting the clean energy transition.

Medical devices like pacemakers and radiation therapy equipment due to biocompatibility.

Chemical catalysts in petroleum refining and pharmaceutical synthesis.

With iridium reserves concentrated in limited regions and mining costs soaring, recycling becomes a strategic solution to secure supply chains.

The Process and Benefits of Iridium Recycling

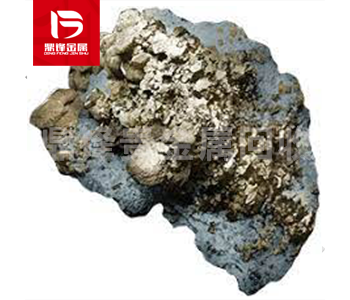

Iridium recycling involves extracting the metal from end-of-life products, industrial scrap, or catalytic converters. Advanced techniques like electrolytic refining, hydrometallurgical processes, and plasma treatment enable efficient recovery of high-purity iridium. For example, discarded electronics or spent catalysts are dissolved in acid solutions, followed by selective precipitation to isolate iridium compounds.

Recycling iridium reduces reliance on primary mining, which is energy-intensive and environmentally disruptive. Recovering 1 kg of iridium from scrap can save over 10,000 kWh of energy compared to mining new ore. Additionally, it mitigates geopolitical risks linked to limited raw material sources.

As industries prioritize circular economy models, iridium recycling will gain prominence. Innovations in nanotechnology and urban mining—extracting metals from e-waste—will further enhance recovery rates. Governments and corporations are already incentivizing closed-loop systems to align with ESG (Environmental, Social, Governance) goals.

Iridium recycling is not merely a technical process but a necessity for sustainable industrial growth. By transforming waste into valuable resources, we safeguard both economic resilience and ecological balance for future generations.